Introduction To Robotics And Robot Making

The Terminator. R2-D2. BB-8. Megatron. WALL-E. For years, robots, automatons or otherwise synthetic assistants have been part of our popular culture. While they’ve mostly been restricted to the silver screen, thanks to increasingly affordable and powerful electronics throughout the last couple decades, building a robot has never been easier.

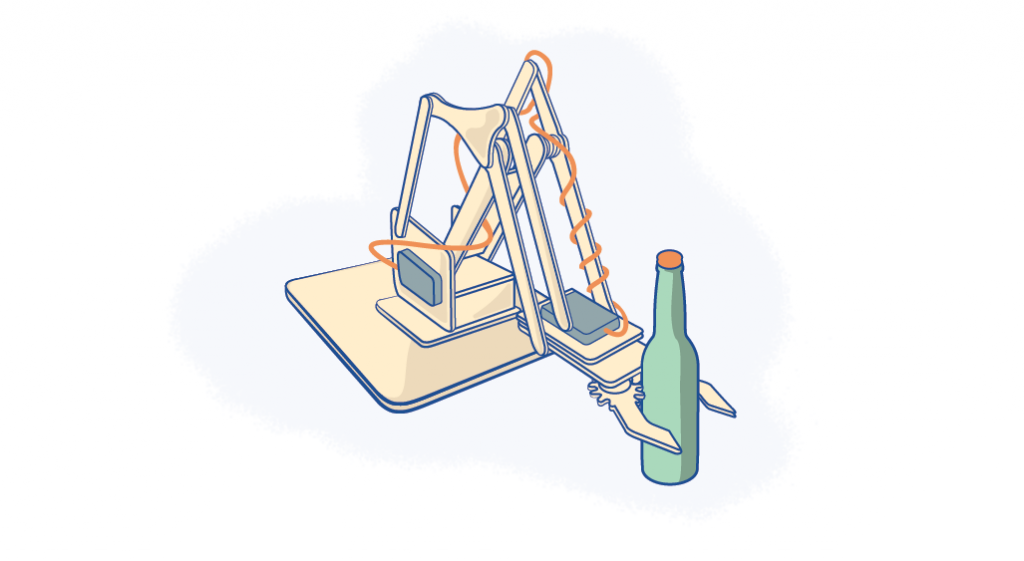

Although robotics is more accessible than ever (such as the MeArm illustrated above that you can build with nothing but a screwdriver and enthusiasm), any robot is a complex system and requires a basic understanding of electricity, mechanical design and programming to create. Never fear! This article will walk you through the elements of robotics, custom robot design considerations, what’s needed to start building a robot PLUS tons of laser-cut design ideas to spark your creativity so you can sell your bots for a profit or cleverly use them to build a brand.

While making robots can be challenging, there’s nothing quite like taking raw materials and making them come to life. Let’s get started!

The Elements Of Robotics

These days, there are endless kinds of robots being built by amateur makers and engineering companies alike. And the capabilities of these robots are growing exponentially.

MIT’s Cheetah 3 robot can now leap and gallop across rough terrain, climb a staircase littered with debris, and quickly recover its balance when suddenly yanked or shoved—all while essentially blind.

The 90-pound mechanical beast (about the size of a full-grown Labrador) is intentionally designed to do all this without relying on cameras or any external environmental sensors. Instead, it nimbly “feels” its way through its surroundings in a way that engineers describe as “blind locomotion,” much like making one’s way across a pitch-black room. Read all about it here.

And just look at what Boston Dynamics has built. Atlas, as it is known, can not only walk but also do parkour.

_

Now that’s some high-level stuff! While Atlas is probably not going to be something you build at your kitchen table or in your mom’s basement, it has many of the same characteristics of less complex builds such as combat bots or autonomous remote control cars in that every robot begins with the same four essential robotics elements.

Mechanisms

Making robots move is a crucial part of robotics design. This is where designing mechanisms, or mechanical engineering, comes in. While mechanical engineering speaks more broadly to machine design, robot designers will be specifically focused on motors and gears, and how to best use them to get the motion desired from their robots.

This usually involves prototyping individual moving parts before attempting to put the whole robot together, but it can be as simple as adding wheels to a DC motor. The level of complexity depends on the kind of robot intend and the way the robot will move.

If designing mechanisms is new to you, the book Making Things Move by Dustyn Roberts is a good place to start.

Electronics

Another fundamental skill required for building robots is circuit design, a.k.a. electronics. An understanding of electronics and microcontrollers (such as Arduino or Raspberry Pi) will allow you to make the right choices in motors, components and power for the robot being designed. Also consider both the functionality and physicality of your parts.

A basic understanding of circuits allows engineers to build a simple robot (such as an RC car) with plenty of online support, documentation and kits available from the maker community. It may seem like an intimidating part of your project, but luckily Instructables has created an easy guide to basic electronics for robotics to push you in the right direction.

Programming

Once you have an electrically sound circuit and mechanisms that are ready to move, it’s time to program the microcontrollers used in the circuit. The microcontroller is the brains of the robot, which needs instructions so it knows how to act and/or react to the surrounding world. (Learn how to choose a microcontroller here.)

For example, a distance-sensing robot needs to be told how to take input from its distance sensor and how use this data to inform its action. In the same way, an RC car needs to know which joystick buttons initiate forward movement vs backward movement vs turns.

The microcontroller chosen will dictate the programming language used and how that program is uploaded to the microcontroller. An Arduino-based robot uses the Arduino programming language and can be uploaded through the Arduino IDE. A micro:bit robot uses the visual learning language make:code and is uploaded through a file drop on the desktop. A Raspberry Pi based robot uses the python language, which can be programmed directly through the chip when hooked up to a monitor and keyboard.

Fabrication

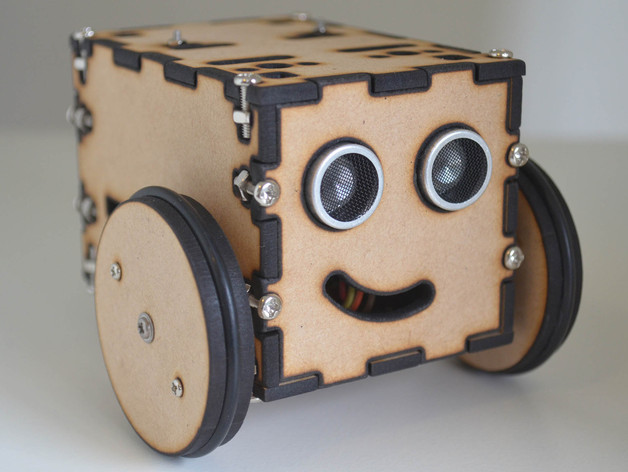

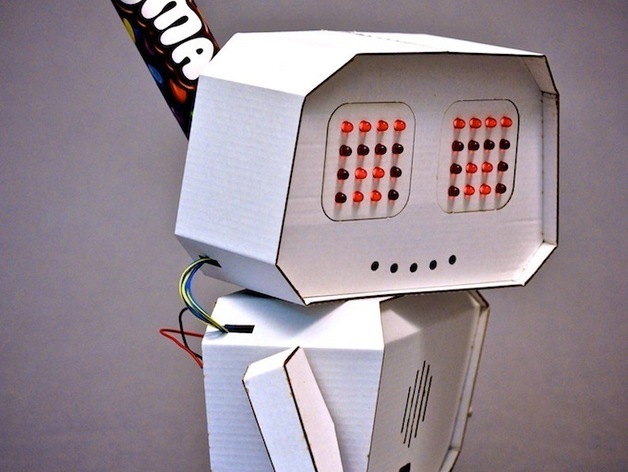

Fabrication—the final step in building a robot—is where the components are put together into the encasement or enclosure made for the robot. With the development of accessible digital fabrication tools such as laser cutters, CNC mills and 3D printers, amateur robot designers are able to make refined enclosures that look professional—without the expensive overhead costs of major manufacturing operations.

The robot enclosure design and chosen materials all depend on what kind of robot being made and the purpose it serves. While enclosures are practical for extending the mechanisms and protecting the precious electronics found inside, engineers can also use enclosures to give the robot personality, express the intended interaction and offer feedback on how to use the robot.

Custom Robot Design Considerations

Once the four elements of robotics are understood, it’s time to talk about design considerations. This includes everything that will impact the design of the robot: The environment it will traverse, the power needed to move, the senses it needs to perform desired tasks, the materials to make the body/chassis and the overall aesthetic style.

Environment

Will the robot move and, if so, what kind of terrain will it navigate? Does it need to withstand any amount of dust or water ingress? Outdoor elements don’t come into play as much if the bot will be kept safe from the elements in your home office. But imagine where the robot will go and how much environmental abuse it needs to withstand. This impacts your choice of materials, the design of robot mechanisms and the overall enclosure.

Power

Will you choose the freedom of batteries, or can you live with your robot being tethered to a wall for power? Every motor, sensor, processor etc. needs some amount of power, so you must determine how much power each component draws and how long you want the robot to be operational so you can factor power requirements into the overall design.

It may seem trivial, but choosing the right kind of power system is one of the more constraining aspects of robot design. As such, it’s smart to consider the power system first before designing any electronics project. And always remember to choose electronics parts that are rated for the power system being used and vice versa. Too little power and the parts won’t work, while too much power might fry the parts.

Senses

Need to avoid the nearest wall? You must have a proximity sensor. Want to follow the sun? Grab some photocells. Interested in turning on when someone is nearby? Motion sensors please. There are countless sensors you can interface with any robot. Consider all the different kinds of information the robot needs to acquire from the physical environment and how this data can be leveraged to make the robot move as intended.

Body/Chassis & Material

How much will the robot weigh? Will popsicle sticks work, or have you entered into custom machined aluminum territory? Are there practical attachment points for sensors? How secure is the battery and can you easily access it for a hot swap? The body of the robot can be as simple or complex as you like, but arguably the best robot designs allow for flexibility, which facilitates an agile prototyping and build process.

One of the coolest examples of how material choice influences how a robot operates has come out of Massachusetts Institute of Technology’s Computer Science and Artificial Intelligence Laboratory (CSAIL). This real-life Transformers-style robot uses sheets of smart material that fold into specific shapes when controlled by magnets. This gives the robot a shape-shifting ability and allows it to walk, roll, sail and glide. Read all about it here.

Style

Once all of the utilitarian requirements are covered, the fun can begin. How will you add personal flair to your bot? Giving the bot facial expressions is one way to add personality, and the PopPet (a fully open hardware DIY robot kit) is a fantastic example.

With its interchangeable faceplates, PopPet can express different personalities or moods. Want PopPet to be surprised, sad, happy or even turn PopPet into a cat? There’s a faceplate for that. And since this is an educational robotics platform, there aren’t restrictions on how much you can actually modify the PopPet, making it easy to learn what goes into making a robot without any prior mechanical or stylistic knowledge.

Most engineers pursue designing a robot because they have a task to be automated. While creating practical robots is fun, sometimes designing ones that are impractical can be an even more exciting challenge. Thus, no conversation about robots would be complete without mentioning Simone Giertz’s Shitty Robots. While in pursuit of automation, these craptastic machines make everything worse and more complicated! Read more about her in this TechCrunch post.

Whether you’re making a shitty robot or one that’s potentially award winning, the overall robotics design process is generally the same. From defining the problem, researching and designing, and creating a prototype to building, testing and evaluating your robot, you’ll definitely want this checklist from Galileo to keep your project on track.

How To Start Making Robots

Ok, enough thinking. Let’s do something already! Here are the practical steps to take and the materials needed to really build a real robot.

Robot Kits

Buyer assembled kits are a popular choice for those that want to learn how to build, code and play with robots. This is a great way to initially get into making and also a viable way to sell complex creations.

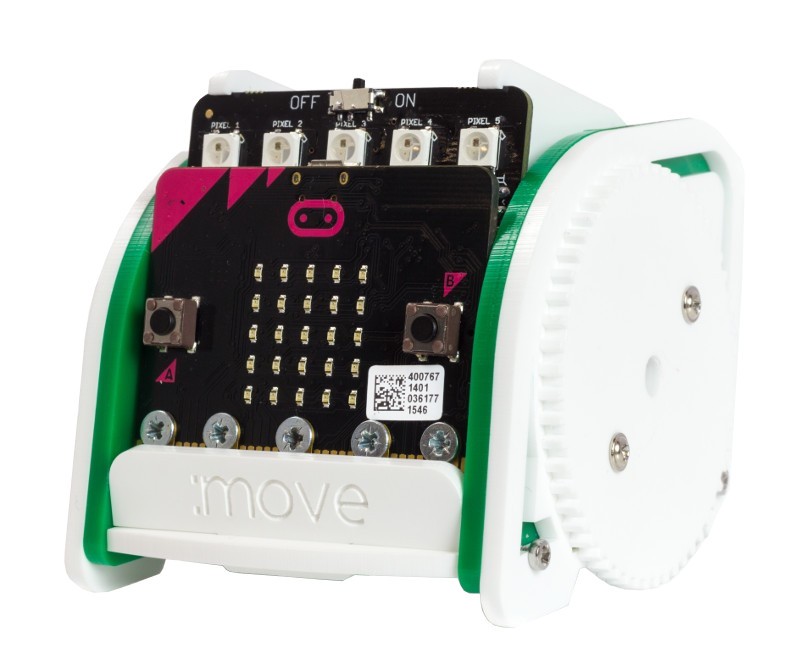

For total beginners, a micro:bit robotics kit is a good place to start. The micro:bit is a microcontroller board designed by the BBC specifically for educational purposes. Thus, this particular microcontroller is the easiest to use when learning new concepts because it uses a programming language called makecode, which is a visual block based language perfect for beginners. SparkFun has a fantastic micro:bit robotics kit, while kitronik can hook you up with a micro:bit robotics arm kit.

Another fun introduction to robotics for beginners, the :MOVE mini buggy kit teaches users about basic physical computing concepts and how to use servo motors. This two-wheeled robot is suitable for autonomous operation, remote control projects via a Bluetooth application or being controlled using a second BBC micro:bit as a controller via radio functionality. The buggy also has 5 x RGB individually addressable ZIP LEDs (NeoPixel compatible), which can be used as indicators, reverse lights, etc. It’s also possible to add a pen or other extra parts to the kit to increase the range of tasks for which it can be used.

Once you get the basics down, a really neat robot kit by Petoi (who specialize in pet robots) is Nybble—described as the world’s cutest open source robotic kitten. Its purpose is to make programming and robotics easy to learn and understand, all in one adorable package. But don’t let the cute-factor fool you. This is a legit Arduino-driven robot that stores instinctive “muscle memory” to act and react with and to the world around it.

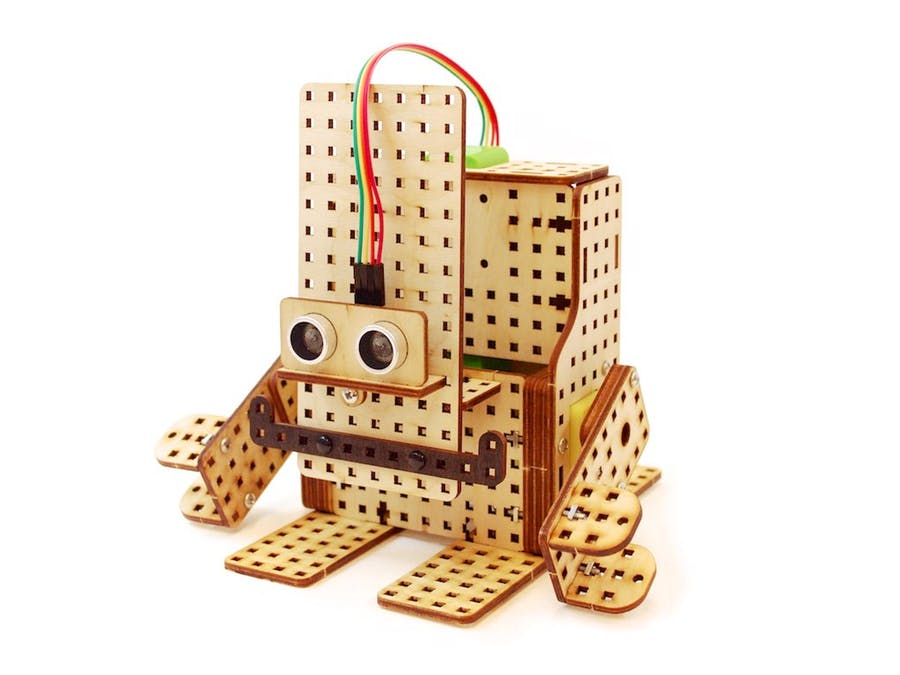

If cats don’t make you purr with delight, then maybe this Gorilla Robot kit will have you swinging from the treetops. This laser cut guy can be controlled with a smartphone or tablet over Bluetooth and programmed to avoid obstacles with a distance sensor. You can also add light sensors to the eyes and program it as a light follower. This kit is a great open-source project for anyone wanting to practice their robotics skills before designing their own beast.

How To Construct A Robot

Once you’ve got a few kits completed, it’s time to graduate to creating a robot design from scratch. It can be quite overwhelming, so why not learn how to make a simple robot by following a tutorial? Instructables is chock full of user-submitted builds for bots of every caliber, and there’s even an online robotics class to walk you through the process.

For even more robot-centric design, the Let’s Make Robots community is not only all about building robots but also sharing the nitty-gritty details and challenges encountered when doing so. It’s really a great resource and has one of the friendliest bot-building communities around.

Robot Design Software

When designing on your own, you’ll need the proper software. Any vector design software is a great beginning tool for making things such as mounting plates and simple chassis, and you can get by for many years using just Adobe Illustrator, a home printer and access to a laser cutter for most designs.

But to make custom robots, you’ll want to add a CAD tool to your belt. This kind of 3D modeling is essential for more intricate designs, and Fusion 360 is a great multi-purpose CAD tool.

If you want to tackle more elaborate concepts without needing a degree in computer science, check out EZ Builder from the EZ robot folks. It is much more accessible robot maker software for tasks such as computer vision and motion control.

Robot Hardware, Parts And Tools

Sure robotics can turn into an expensive endeavor depending on how elaborate your robot’s functionality is, but it doesn’t have to break the bank. For a investment in few tools and robotic accessories (plus access to a laser cutter), you can accomplish a lot with a very little:

Tools

– Soldering Iron

– Helping Hands

– Wire Cutter/Strippers

– Flush Cutters

– Benchtop Power Supply

– Small Screwdriver and Bit Assortment

– Hot Glue Gun

Components

– Battery Holders/Compartments

– LEDs

– Resistor Assortment

– Power MOSFETs

– Toggle Switches

– RC Analog Servos

– Raspberry Pi

– Arduino

Suppliers

Hobby King is one of the best resources for RC components and all things drone related. With a huge catalog, the selection of motors and servos is one of the best for DIYers.

Robot Shop has a little bit of everything. Plus, it’s one of the only resources for the high-end components that you’d struggle to find elsewhere.

Sparkfun not only offers a great selection of components, breakout boards and kits, but it also has tutorials galore plus a yearly autonomous vehicle competition that’s not to be missed.

Adafruit has one of the largest spreads of sensors, displays and components around. Plus, there’s high-quality documentation for nearly everything sold.

Thrift Stores have a treasure trove of old printers (in particular) that are chock full of decent DC motors, gears, pulleys and other mechanisms, all of which are quite salvageable.

Robot Design Ideas

Robotics is a broad field, and there are many types of robots that you can build as a product to sell or use promotionally to build a brand. Here are some of the main classes of robots for inspiration.

Simple Robots

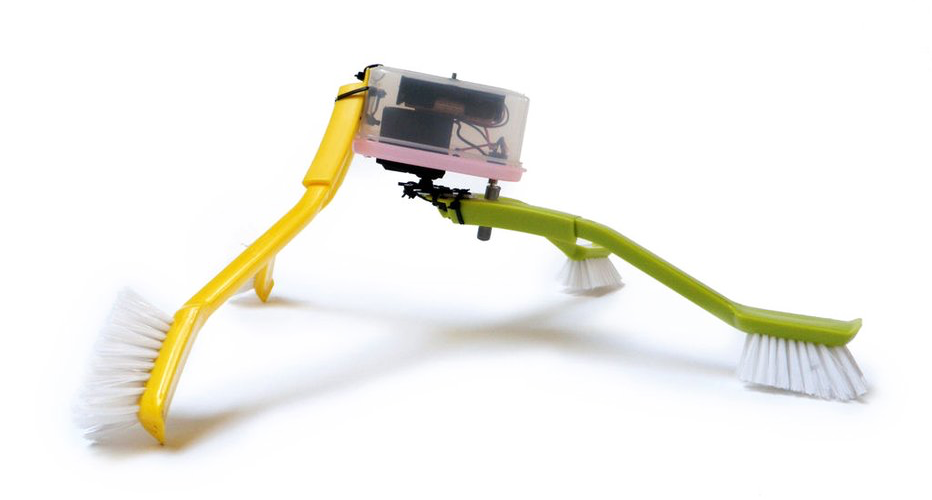

Why complicate things? If you want to skip all that programming business and stick to simple robot ideas, the quite humorous Randy Sarafan has you covered. He’s designed many different simple bots that use a variety of household materials and require minimal wiring.

While his ideas aren’t laser cut, they’re too clever not to include in the discussion. We’re kinda partial to the Skitter Bot, which came into this world “as result of a chain reaction of exploded cosmic energy.” According to Sarafan’s current estimates, this chain reaction took roughly 13.7 billion years to complete. When put into such context, it becomes quite clear just how long it takes for a near-perfect walking scrub brush bot to come into being.

But don’t be fooled by its simplicity, though. This kind of scrub bot didn’t just materialize overnight when Sarafan zip tied a bunch of scrub brushes together. No! “There was an ineffable cosmic plan that led up to this bot’s creation, going back well beyond the day when man, through genetic mutation, first evolved the ability to manufacture zip ties and scrub brushes,” he says. “This bot is a bona fide cosmic child.”

In addition to cleaning, robots can remind all those born without a green thumb to water their plants. These Plant Friends contain a moisture sensor system that monitors the air temperature, humidity and soil moisture of indoor plants, and they send alerts via email or text message when plants are thirsty. Your geraniums will thank you.

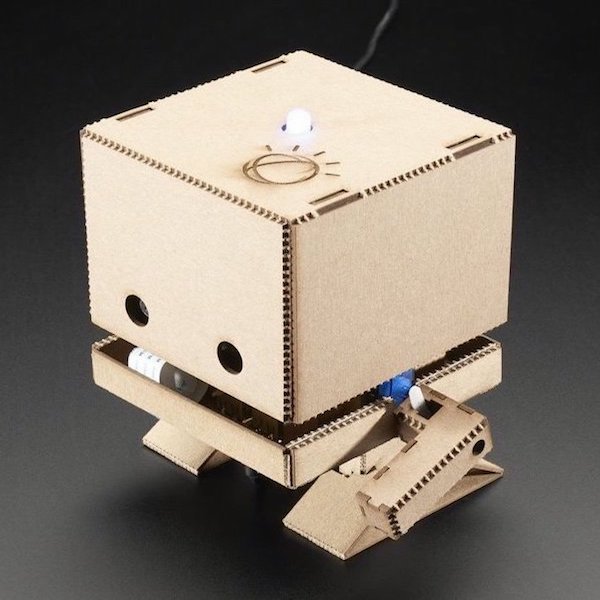

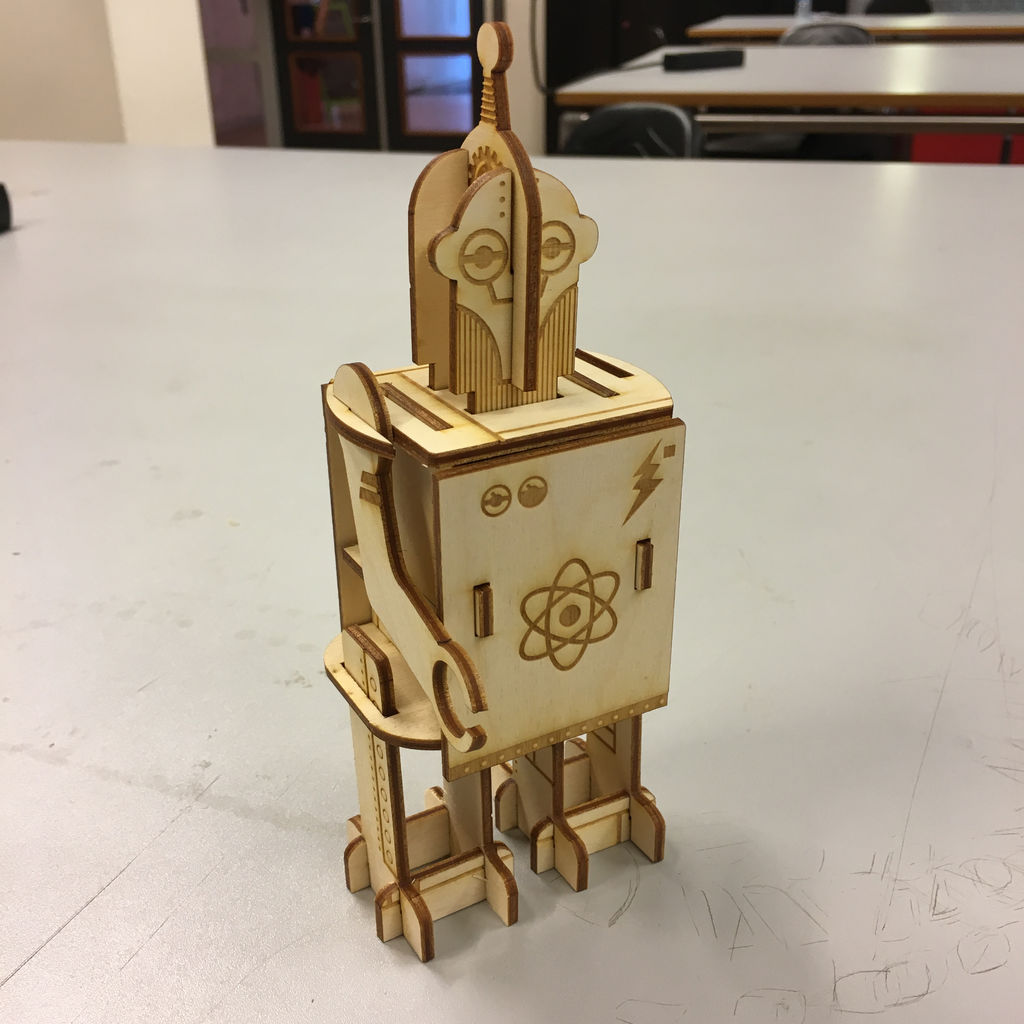

If you like the cute characters above, we’ve got another for ya: TJBot. Born at IBM Research with all kinds of personality, TJBot is a DIY template to learn, experiment and explore AI with IBM Watson. Laser cut this cutie then use the open-source, step-by-step recipes—a.k.a. coding instructions—designed for a Raspberry PI to connect your TJBot to Watson developer services so you can teach it to dance, tell a joke or carry on a conversation.

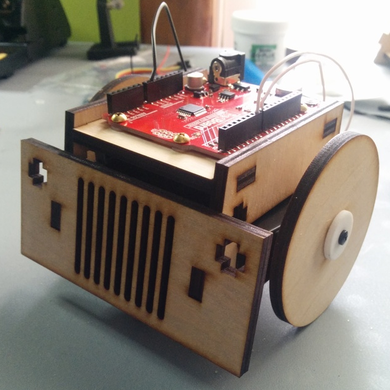

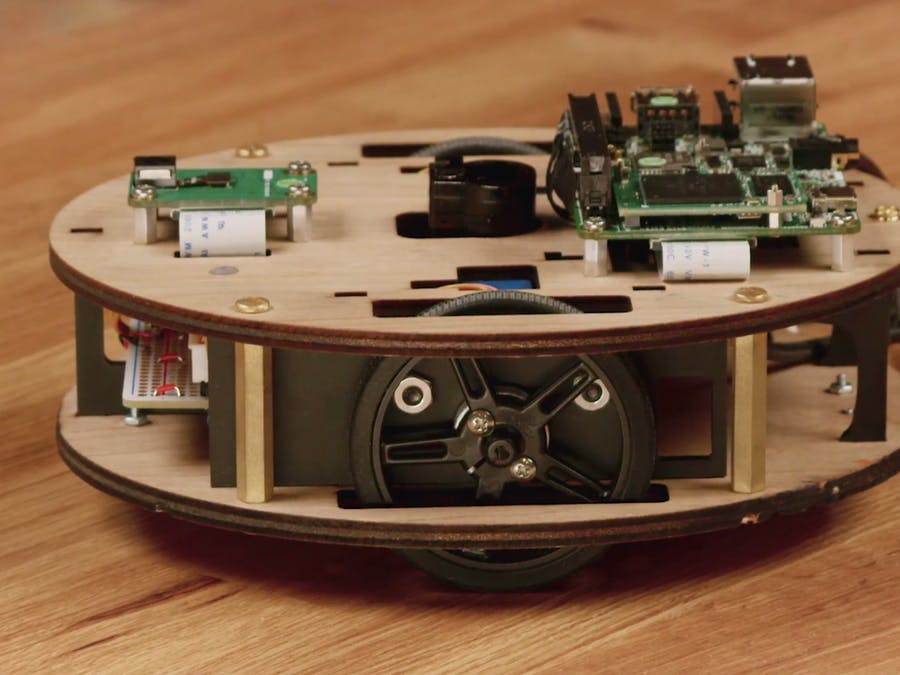

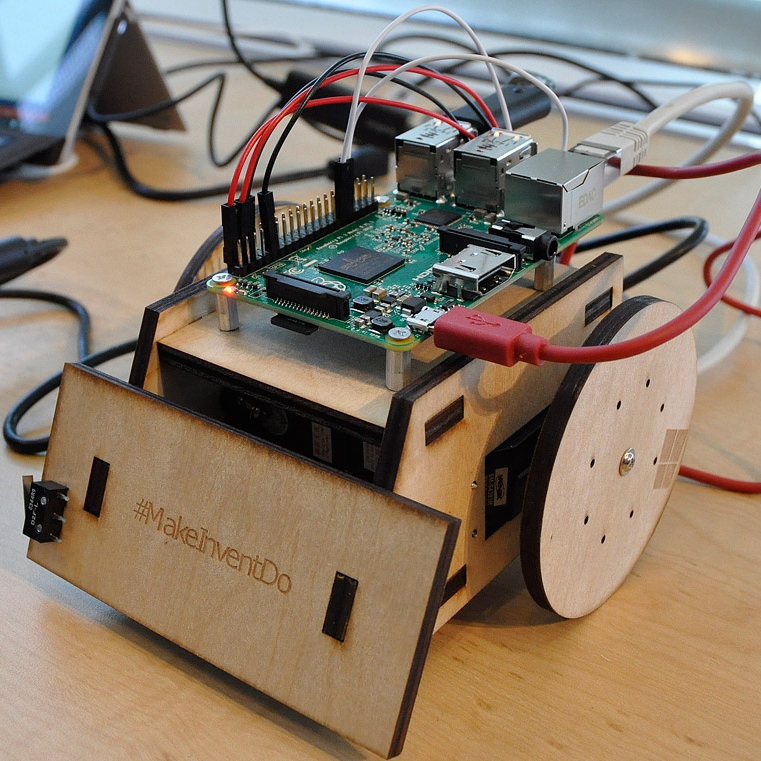

Wheeled Robots

A robot with wheels is one of the best designs for beginners to tackle. You can get started with just a couple of motors and some decent-sized batteries to roll a wheeled robot along. Wheels allow a quick form of locomotion and are the cheapest way to get bots going.

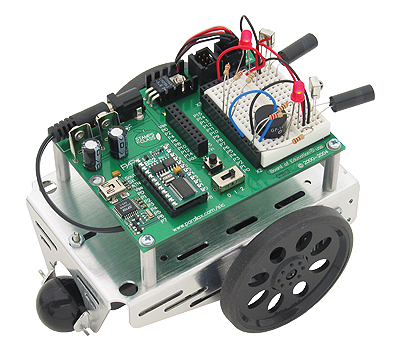

Having two rear-mounted wheels allows for differential steering, which is one of the simplest means of robotic directional control. Parallax’s BoeBot is a very common wheeled platform that offers a lot of features in a standard little package.

Toy Robots

Alright, so there’s not much of challenge when your main hurdle is spending a few dollars on a mass-manufactured robot toy. Not only can you learn from the mechanisms the robot already has, but once your robo-skills have improved, you can tear your store-bought bot apart and use the chassis or precious internal electronics for your own designs. RC cars or tanks are great, cheap ways to get a prebuilt drive mechanism that can easily be expanded upon.

There are toys that you can tear apart and rebuild, but why not start with one meant to be built and rebuilt? The Lego Mindstorms series has come a long way in the past years and is now a powerful, yet accessible, robotics exploration kit. Ignore that age label on the box because this platform is for everyone. It’s a wonderful way to try out new designs without the cost of consumption you’d have with other robots.

For a toy robot that doesn’t have the look of off-the-shelf components, check out this laser-cut basketball robot that gives you a buddy with whom to shoot, score and make the crowd (even if that’s just your cat) go wild. This tutorial is a step-by-step guide for a simple and small differential-drive robot that uses the Intel® Edison. See it in action here. Bonus: You’ll get to know a few more tricks on how to use Mini Breakout Kit and set up a node.js server for the communication.

Combat Robots

If you’ve ever hosted a miniature sumo-bot competition, you know that once the battles begin, it’s really quite thrilling. Building a fighting robot gives your design a better sense of purpose as the goals are clean cut and the stakes are quite high!

If you want to build the kind of thrashing, fire-breathing monster you might find in TV shows such as Battlebots or Robot Wars, then be prepared to spend in excess of $10,000. Luckily, combat robotics has many-a-weight-class that spans from nano-weight to super heavyweight behemoths, so you can find a style that matches your skills and budget.

To get started, the Sumobot Jr. is a great beginner model that can hone your skills while keeping the budget in check. Get the laser cutting files to build the chassis here.

If you can’t find a local competition to test your new creation, why not start your own? Combat robotics is much more about community than conflict, and would give your newfound group a regular goal to work around that leads to better participation.

Walking Robots

Walking may seem like second nature to you and me, but for robots, it’s one of the most challenging builds.

Bi-Peds: Humans, birds and (occasionally) apes walk bipedally. And there’s good reason there’s not an abundance of bipedal locomotion in nature. Walking upright on two legs is actually a form of controlled falling, and it requires complex synchronization of many different muscles and constant adjustments to control the center of balance. You’ll often see “walking” robots that actually shuffle around with short steps to better keep upright, but some are more than meets the eye.

While building a biped that moves around like a person is a significant challenge, less experienced robot builders can get started with their very first biped with Otto DIY. This sweet open-source robot comes with a downloadable 3D model for printing the body as well as all the electronics/programming you need to get Otto going—from walking, dancing, making sounds and avoiding obstacles. You can build Otto in less than a day and be able to say that you built a functional biped!

If electronics and programming aren’t your thing, then opt for the laser-cut windup robot made from an example in the book Build Your Own Robots, Assemble Three Robots by Steve Parker and Owen Davey (in Dutch: Bouw Je Robots, Maak Zelf Drie Robots Die Echt Kunnen Bewegen). Get the plans via Instructables here.

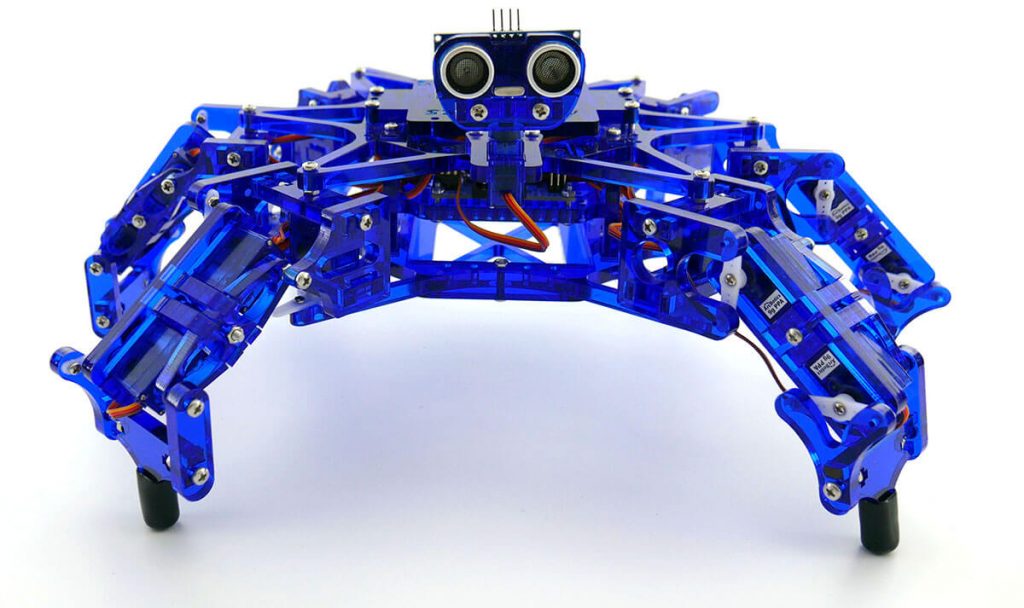

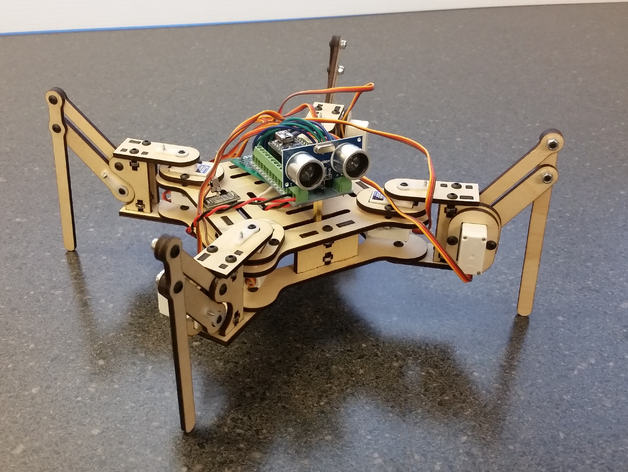

Hexapods: Six legs are better than one (or two, or three…). Hexapods are some of the most common legged platforms since they are inherently more stable, and the algorithms for locomotion are, while complex, still simpler than those required for a tall biped. And once you’ve got it stable, you can do some crazy things with your platform.

If you’d like to tackle one of these electronic insectoids, invest in a few more piggy banks. Since the most common designs require three servos per leg, the price tag for even a basic hexapod can be quite hefty.

That said, there is an affordable build available. Hexy the Hexapod is a fully articulated hexapod robot kit that provides a platform to explore advanced robotics, kinematics and programming. Hexy makes complex robotics less costly, easier to learn with the tutorials and documentation, while being radically more fun—and cute! At the same time, its built with completely open-source hardware and software, making discovery and extension as easy as building it in the first place.

Hexy has six legs, 19 servo motors and is powered by Arduino, while maintaining a price four-to-10-times less expensive than current hexapod robots. Great for students 15+ years old who are exploring advanced robotics and kinematics as well as engineers who are looking for an open-source platform.

Flying Robots

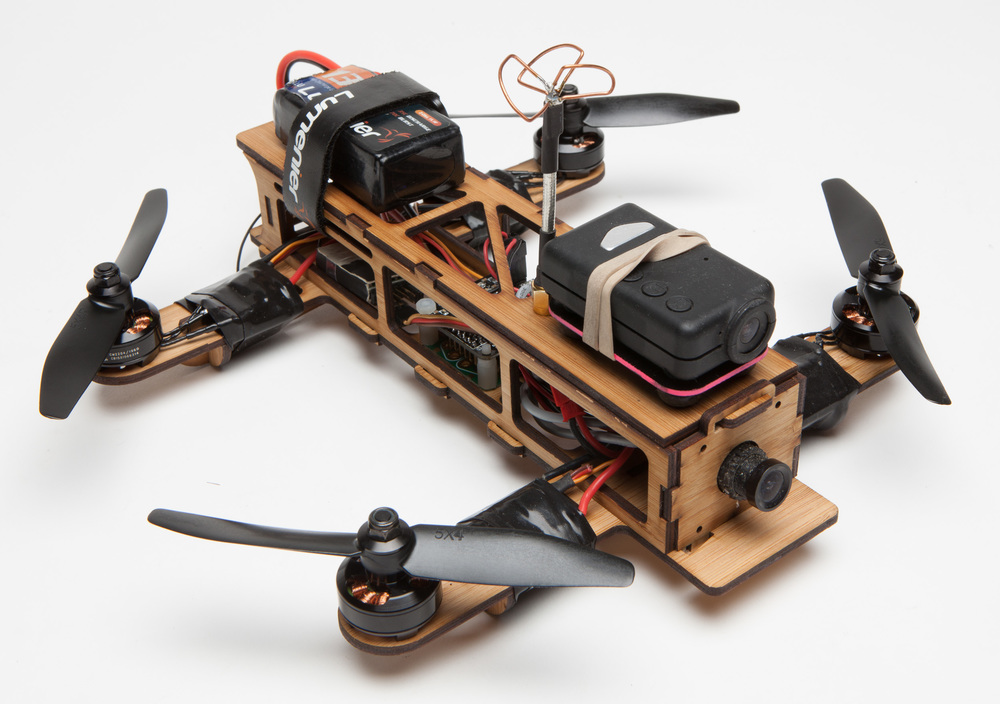

Making drones and racing robots has never been easier and more affordable. Thanks to the explosion in cellphone technology, motion sensors have become faster, cheaper and more capable. Because of these advanced accelerometers, gyroscopes and magnetometers, keeping track of a robot in 3D space is now possible for tinkerers of every skill level.

Multicopter drones require precise measurement of their position so they can hover and produce stable flight. While you can buy individual components for flying robots, it’s increasingly common to find controllers that have most of the electronics integrated, so you just need the motors, battery, remote and a frame (which can be easily laser-cut).

When it comes to drones, the Shendrone by Andy Shen is cost effective with structural material laser cut from bamboo ply, and a snap-fit assembly means no glues or screws to slow down the construction process. That’s about as easy peasy as it gets.

Once you get the hang of flying drones, you might want to strap a wireless camera on board and enter the growing sport of drone racing. These high-speed aerial robotics competitions are quickly gaining popularity around the world. Who wouldn’t want to fly?

Artistic Robots

Don’t worry art students, the robots are coming for your future job, too. But the good news is that you can take a pass on your basket weaving class and upgrade your projects with a basket making robot. Then take all of the inventory and open your own basket boutique. To entice customers to come in, use this friendly bot (made from laser cut MDF) to decorate your storefront windows.

You’ll also want some custom signs for all your advertising and price tags, right? Say goodbye to your human employees, and put these drawing robots to work so your can save some precious $$$.

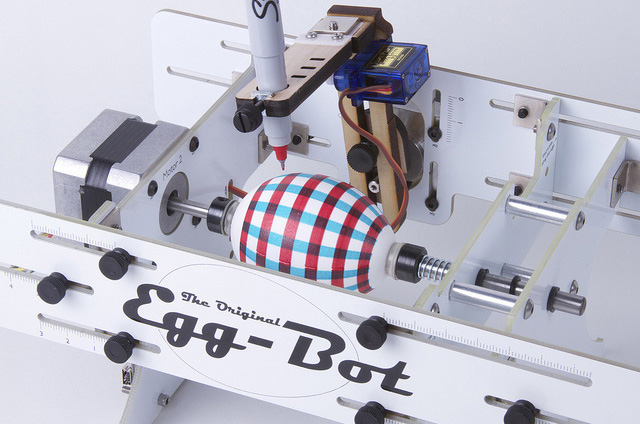

What if your customers want more that baskets? Diversify your product line and start selling custom decorated eggs thanks to this incredible Egg Bot.

Robots With A Purpose

Sometimes we make robots just for the heck of it, and sometimes we make robots to serve a specific function. For example, the laser cut Android Things Draw Bot will take your selfie and then make a drawing of said selfie within minutes, making this one of the best party companions around.

Trying to cut back on your sweets consumption? Or maybe you just want your coworkers or classmates to stop stealing your treats. In either case, the Arduino Ninja Smarties Robot is the robot for you. This open-source, laser-cut robot takes money in exchange for Smarties, M&Ms or Skittles. What a delicious idea!

Builder Robots

Fancy a new wall for your home? Laying bricks is backbreaking work. Thankfully, this robot arm has no back to break and will happily lay bricks in an elaborate pattern so long as it has power…and plenty of bricks, of course.

Need an intricate geometric lattice for your minimalist lair? These “metabolic” robots can assemble trusses for elaborate structures much like organic systems.

_

Perhaps you are looking to solve homelessness across the globe, or maybe just offer an affordable housing solution to desperate millennials. These days, 3D Printing Home Robots are an exciting prospect for affordable housing options. The incredible machines can print homes for less than $10,000 and in less than 48 hours, making house building cheaper and faster than ever.

Complex Robots

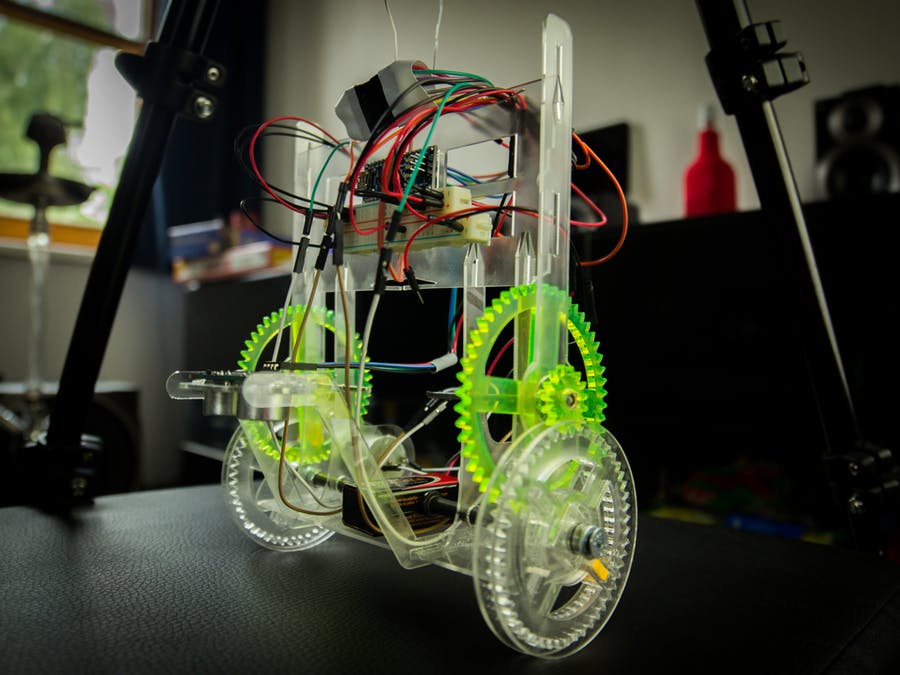

Looking for more of an engineering challenge? Test your skills with the self-balancing robot. It’s laser cut from acrylic—imagine all the color possibilities! In addition to constantly seeking the brightest spot in the room, this laser-cut-gear machine balances itself on only two wheels. It’s a feat in both mechanical engineering and programming.

Another ambitious laser cut robot is the mePed Quadruped Robot by Scott Pierce. It features a completely laser cut chassis, four—that’s right, FOUR—legs and eight degrees of freedom. This means the robot can move on the following axis: up and down, forward and back, right and left, and pitch and roll. Pretty complex! This design offers a ton of movement options for your bot and is quite an accomplishment both mechanically, electronically and programtically.

Robots For Branding

It’s easy to imagine being able design, make and sell robots for a profit. But can they be used in branding applications? You bet.

When you’re a tech giant like Microsoft, status quo promotional products for an annual developer conference just won’t do. Event attendees expect more. Much more.

So the company went to the drawing board (literally!) to create the ultimate tradeshow giveaway for its Build Developer Conference—a Sumo Robot.

But this was no easy task. The engineer in charge of the project had never created event swag like this nor designed a custom giveaway on this grand a scale. In fact, many of his peers didn’t think it was possible to pull off the project in the timeframe available. There were so many moving parts, the platform was liquid, the timeframes were light and he was running up against budgetary constraints.

Undeterred, he set out make it happen. Find out if he pulled it off here.

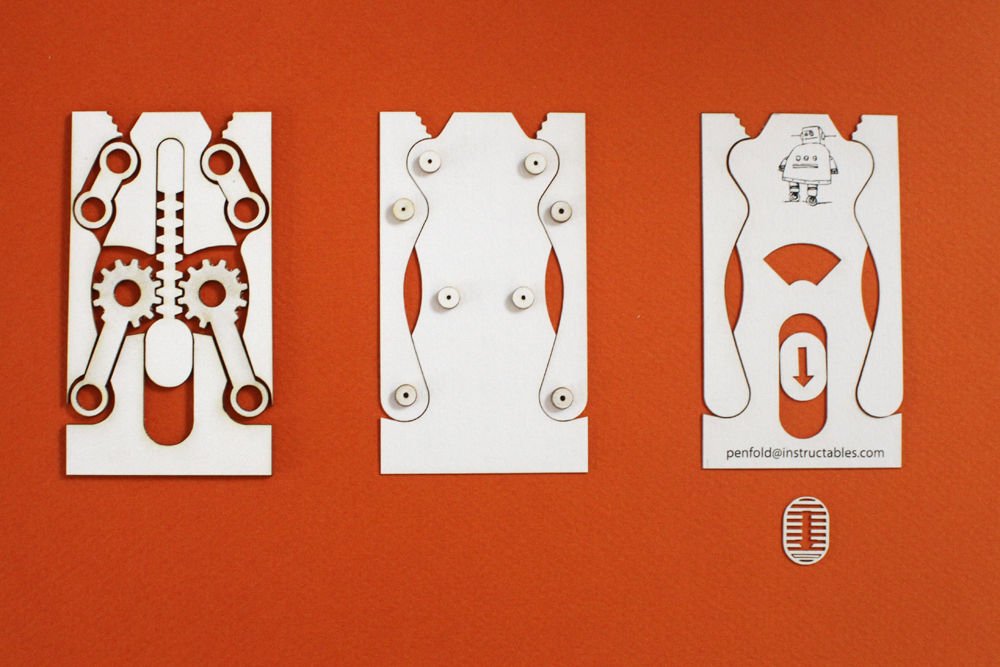

Designing a full-scale operational robot isn’t always in the budget for branding campaigns. So how can you show off your robotics chops on a small scale while still making a big impact? Check out this robotic claw business card and show everyone you’re a robo-ringleader.

Need more inspiration for all the kinds of robots you can make? Pinterest has you covered (as always), and check out this compilation of the 10 best robotics articles.

Bringing Robots To Life

We’ve only scratched the surface of what’s possible in the wide world or robots that you can make to sell or use to build a brand. It’s a very broad and deep field that incorporates numerous facets from both the arts and sciences in order to produce a working thing. That’s the fun of it though, the challenge, the risk of failure and the possibility of bringing an idea to life.

Additional thanks to DJ Harrigan for providing supplementary content and Lisa Horn for writing and content editing.