Laser cut wood & engraved custom wood parts - order online, delivered same day.*

On demand prototyping & production, same day from $50 for just 1. 93% off for 10,000.

"I liked the automated process. Basically, if I had to get custom quotes from a human every time I had a new design, it wouldn't be worth my time to make my products."

"We see this as the beginning of something huge"

Cloud manufacturing technologies to accelerate your hardware build.

Startups & enterprises rely on our cloud accelerated prototyping & production, to build the next great products.

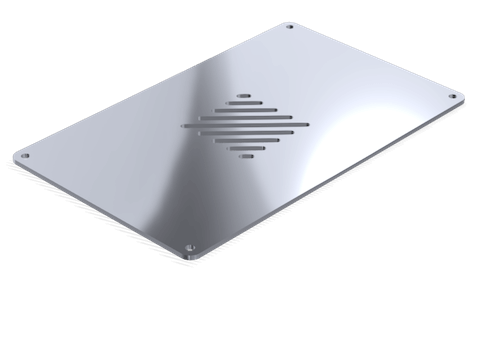

Sheet Metal Fabrication

- ±0.13mm Dimensional accuracy

- 3000x1500x25mm Max part size

- 15x15x0.4mm Min part size

- 1x1mm Min feature size

- ISO-9001, ITAR

- Same day Min lead time

Laser Cutting & Engraving

Sheet Metal Photochemical Machining

3D Printing

Injection Molding

Assembled Printed Circuit Boards

Laser-cut wood quoted, manufactured, and delivered same day from $50

High precision laser cut wood components can solve many engineering and aesthetic problems when prototyping or building a new product. Ponoko has a wide range of materials available for instant quotation of your wood laser cutting project, with no minimum order quantity. The diverse selection of woods exhibit a variety of mechanical and artistic properties to meet your exacting requirements, through a full range of thicknesses.

With simple tabs and joins, you can easily build high quality wooden protective coverings for your hardware, whether its an enclosure or retail packaging. Wooden mechanical components offer an eco friendly, sustainable alternative to plastics and metals, while being lightweight and high performance.

Ponoko’s premium laser cut wood varies from artistic printed MDF to engineering materials such as high quality plywood and cork. Add some retro flair to your product's enclosure or control panel with adhesive backed hardwood veneer, or a touch of tactile quality by using solid hardwood.

Custom laser cut wood parts delivered same day (or money back).

Can laser cutters cut wood?

Despite wood being a combustible material, it is very easy to cut with a laser cutter. While it is a common belief that laser cutters cut materials by burning, they instead use the intense heat of a laser beam to vaporize material (thereby removing it).

Numerous laser cutting technologies exist and it is essential that the right one is used to ensure an even and clean cut. In the case of wood, CO2 lasers are generally preferred as the infrared beam generated by a CO2 laser is easily absorbed by wood.

Ponoko has dedicated itself over the years to provide a high-speed, high-quality laser cutting service for all its customers whether they are individuals looking to prototype their next big idea or a large international engineering business looking to initiate their first production runs. With over 200+ engineered materials of varying thickness and colour, we help accelerate projects by removing the need to research laser-safe materials, provide same-day manufacturing of custom laser-cut wood parts, and provide a level of engineering precision that is unmatched across the laser cutting industry.

Can wood also be engraved?

What type of wood can be laser cut using a laser cutter?

What type of laser technology can be used to laser cut wood?

Ponoko provides wood materials engineered for wood laser cutting, with finishing services.

Ponoko delivers custom cut wood parts, same day from $50 for just 1.

Why cut wood with a laser cutter?

Of all machining methods available to wood, laser cutters present one of the most economical options providing an excellent compromise between precision and speed.

The first major benefit to using a laser cutter with wood is that there are no tooling costs. Cutting wood with saws and routers requires the use of mechanical tools that wear down over time, and this sees a significant increase in cost (especially if the part is complex). However, in a laser cutter, there are no tools that wear down over time, and as such the running costs of laser cutters are significantly lower.

The second major benefit of using laser cutters with wood is that is no need for mechanical clamps to hold the wood stock down. This is due to the lack of any mechanical force from the laser beam, and this allows for extremely intricate parts to be made. At the same time, the lack of mechanical forces also eliminates the need for tabs or breakouts in parts, and this allows for laser-cut wood parts to be a perfect copy of a design.

Thirdly, the use of CNC axis controls and a laser head removes the need for any custom molds or tooling. As such, laser-cut wood parts are extremely cheap to produce, make changes to, and even scale up production rates in real-time.

Overall, Ponoko is a laser cutting company that has years of experience in the field of wood parts. Having served over 33,000 customers and manufacturing over 2 million parts, we are confident in our laser cutting abilities for any wooden part no matter its complexity, size, or production quantity.

How does laser cutting wood compare to other manufacturing technologies?

What disadvantages are there when laser cutting wood?

How thick can laser-cut wood parts be?

Start from just 1 laser cut wood part, delivered same day.

Scale to 10,000 laser cut wood parts, at 93% off.

Is laser-cut wood expensive?

Compared to other materials, wood is one of the cheapest to laser-cut thanks to its support for high-speed cutting, cheap stock, and availability.

One advantage that engineered woods have over natural wood is that they are manufactured from ground-down wood fibres that are then bonded together with adhesives meaning that they are more efficient to produce. At the same time, the fibres used to make sheets of engineered wood can be sourced from waste in other processes thereby maximising the yield of harvested wood.

Additionally, laser-cut wood also presents engineers with numerous post-processing opportunities for prototyping whether it is small adjustments to the shape via further machining, the addition of more cutouts, surface finishes, and construction of 3D shapes. While metal and plastic also present the same opportunities, wood is both safer and easier to machine.

For those needing laser-cut wood parts, Ponoko offers customers the ability to quickly scale designs from initial prototypes to first production runs. Using wood provides engineers with a cheaper alternative before committing to a more permanent material such as metal or plastic, and when production runs are ready to be ordered, discounts on bulk orders can be as high as 93%. There are very few manufacturing services available to engineers that can move from prototyping to full-scale production as quickly and cheaply as Ponoko can.

What is the difference between hardwood and softwood?

Can laser-cut wood use living hinges?

What can laser-cut wood parts be used for?

Trusted by 35,000+ founders, CEOs, engineers, designers & scientists.

Order laser cut custom parts from your laptop, delivered same day.*

From $50 for just 1. 93% off for 10,000.