Laser cut stainless steel parts — delivered the day you order.*

Custom made stainless steel, whether you order 1 part or 10,000 — 99.3% quality record.

"Troubleshooting my design with you and the Ponoko team has been pleasant and very informative."

"We see this as the beginning of something huge"

Cloud manufacturing technologies to accelerate your hardware build.

Startups & enterprises rely on our cloud accelerated prototyping & production, to build the next great products.

Sheet Metal Fabrication

- ±0.13mm Dimensional accuracy

- 3000x1500x25mm Max part size

- 15x15x0.4mm Min part size

- 1x1mm Min feature size

- ISO-9001, ITAR

- Same day Min lead time

Laser Cutting & Engraving

Sheet Metal Photochemical Machining

3D Printing

Injection Molding

Assembled Printed Circuit Boards

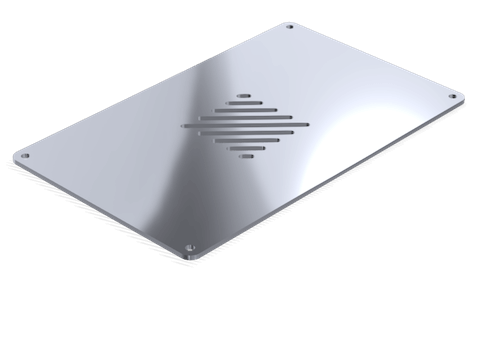

Aluminum Faceplate

Software powered manufacturing service with scalability from 1 to 10,000 parts

When you need corrosion resistance, stainless steel is likely to be your go to material. Ponoko stocks SAE 304 stainless steel (A2 stainless steel) in a variety of thicknesses ready to be laser cut the same day, with no minimum order quantity. 304 Stainless steel is the most common grade of stainless steel, offering a good tradeoff between corrosion resistance, workability and strength. Laser cut stainless steel can be readily bent and formed with standard tooling, and is easy to weld with standard arc processes. 304 Stainless steel does not harden when cooling, which makes it an optimal for both laser cutting and welding. This means it does not require pre- or post- treatment after heating to retain its toughness. Laser cut stainless steel is ideal for mechanical components or external components such as panels and faceplates that require excellent corrosion resistance and high strength.Stainless steel materials online.

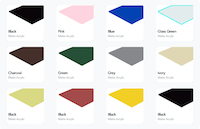

Not all stainless steel is created equally, and not all can be cut using a laser. To ensure that all parts are cut to the highest degree of precision, we have a curated list of materials carefully chosen for their properties including tensile strength, density, and conductivity. All of our materials are engineered meaning they are ideal for precision work, and during the order stage, you can compare any materials on our site, and all materials are available no matter the size of the order.

How we deliver custom cut stainless steel parts same day.

Our software power services combine all needed manufacturing steps for stainless-steel parts into a single process where uploaded designs can be customized and ordered in minutes. Orders with quantities less than 100 ordered before 11 AM are manufactured and shipped the same day, and customers in the San Francisco Bay area will receive their parts the same day (US customers outside this area will receive them the next day). If we can’t deliver on this promise, we will issue a full refund for delivery.

Upload your designs online.

Select stainless steel materials online.

Get online quote in seconds.

Robots produce stainless steel parts.

Track your orders online

Start from just 1 part, delivered same day.Scale to 10,000 parts, at 93% off.

Our customers are leading their industries.

Our ability to produce precision-engineered stainless-steel parts sees us selected by many industry leaders whether it is for medical devices, drones, electronics, biotech, or defense. Our ability to scale orders from 1 to 10,000 allows for precision engineering projects to move from prototype to production in an instant, and our ability to manufacture and ship parts same day allows for daily design iterations which reduce the development time of prototypes from weeks to just days.

Bionic exoskeletons

Ekso Bionics

iOS POS hardware

Aila

Fulfillment systems

Berkshire Grey

Connectivity devices

Twilio

AI plant monitoring

Bowery Farming

iPhone testing stands

Apple

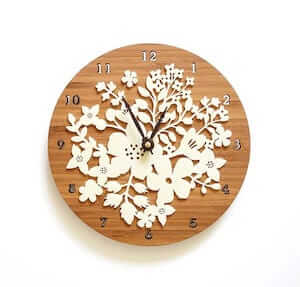

Wall clocks

Decoy Lab

Jewelry

Gio Gio Design

Lighting

Modern Maine

Internet satellites

Astranis

Aircraft

Joby Aviation

Autonomous vehicles

Velodyne Lidar

Scientific devices

Thermo Fisher

Cell therapy systems

Orca Bio

Delivery robots

Cyan Robotics

Laser cutting built for startups & enterprises.

Automatic IP protection.

Your online account terms bind us to protect your IP confidentiality, including a Non Disclosure Agreement.

Automated 30-day payment terms.

Upgrade to business terms today . Checkout online tomorrow. Pay in 30 days.

Free standard shipping.

For all USA shipments. Free material sample too.

Live chat with our technicians.

We’re online Monday - Friday, 9am - 5pm PT to assist you design highest quality & lowest cost custom parts.

99.3% precision part quality record.

When scaling a stainless-steel part up for production it is essential that all manufactured parts conform to the same degree of precision and quality, and we have an outstanding record of 99.3% precision part quality. With over 33,000+ customers from all over the world, and having manufactured over 2 million parts, there is a reason why so many precision engineering businesses choose us for their laser-cutting needs. To further show our confidence in our abilities, we offer a 365-day guarantee on all parts.

Standard quality procedure.

Our software, then design inspector, laser operator & quality manager quality check all orders.

Our promise.

If our software, robots, people or suppliers get it wrong, we’ll re-make & re-ship for free. No pesky returns.

We’re passionate about unleashing hardware creativity to advance humanity.

Nothing excites us more than the next-generation projects we are involved with on a daily basis. Whether a stainless-steel part is being used in a new wearable medical device or being used to research nuclear physics, we strive to unleash the full potential of our customers. Our ability to manufacture and ship parts the same day from just $50 allows for design iterations to be done in days instead of months; something that is essential when advancing humanity.

Trusted by 35,000+ founders, CEOs, engineers, designers & scientists.

FAQ

What is stainless steel and why is it used so much?

Can laser cutters cut through stainless steel?

How accurate are laser cutters when cutting stainless steel?

Is cutting stainless steel expensive?

Can stainless steel be engraved?

Does Ponoko support internal cut-outs in stainless steel parts?

Where can laser cut stainless steel be used?

Order stainless steel laser cut custom parts from your laptop, delivered same day.*

From $50 for just 1. 93% off for 10,000.