Online custom sheet metal fabrication service, for startups & enterprises.

Prototyping & production sheet metal fiber laser cutting, bending & tapping, using 250+ metals.

Contact sales engineerOur sheet metal fabrication capabilities

While maximum part size and thickness can vary depending on the sheet metal being used, our precision capabilities are the same for all parts. All sheet metal fabricated parts have a maximum dimensional accuracy of ±0.13mm, a minimum complex feature size of 1x1mm, and a minimum laser kerf of 0mm. The largest sheet size is 3000 x 1500mm, and the maximum thickness for any part is 25.4mm. The minimum lead time for those in the San Francisco Bay Area is same-day delivery (orders placed before 11 AM), and delivered next day for those within the US mainland.

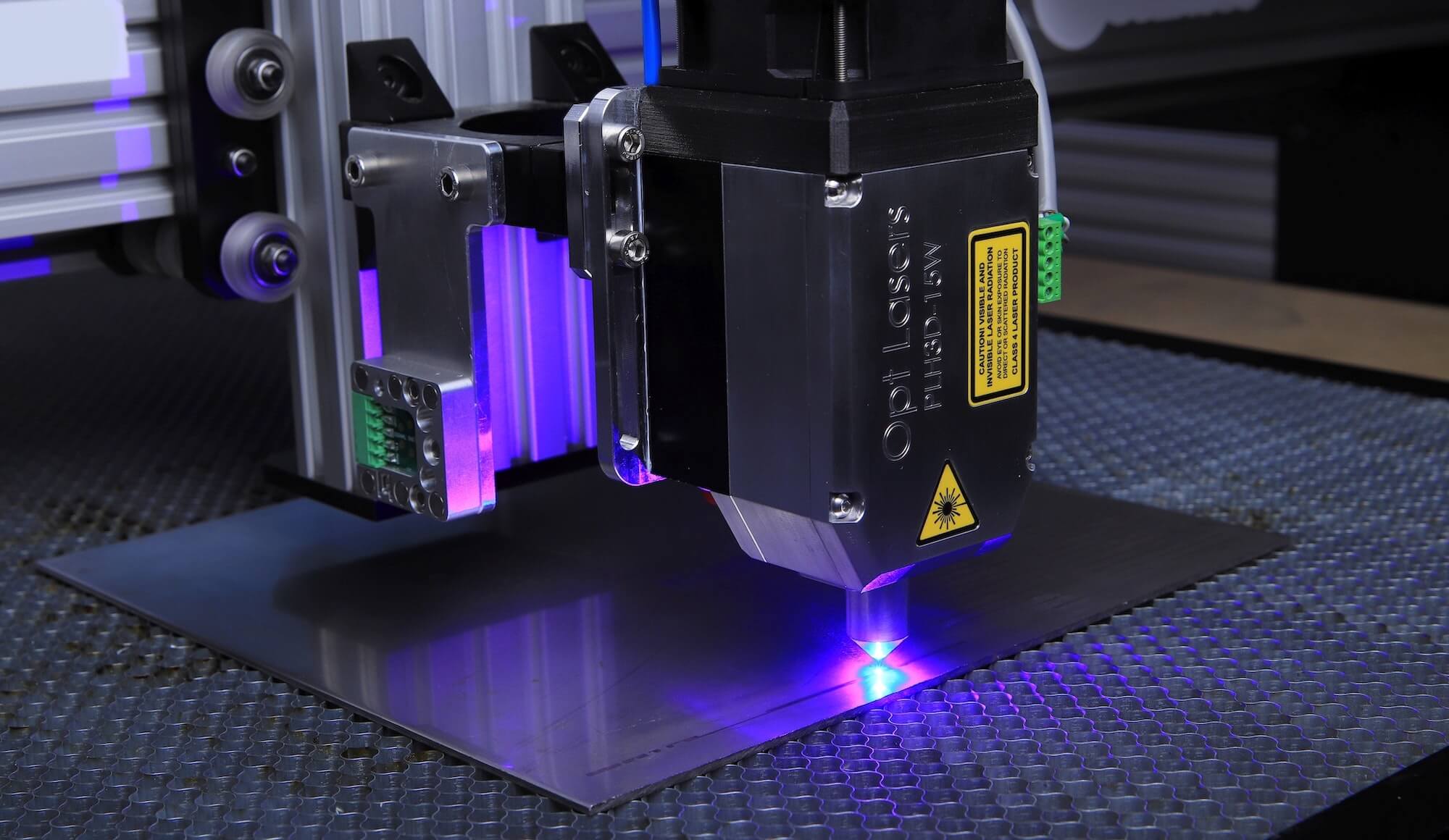

Our fiber laser cutting capabilities

Min lead time

Max laser power

Edge to edge cut tolerances

Laser kerf

Material thickness

Max part size

Min part size

Min feature size

Part quantity

Shipping within USA

Guaranteed tolerances

Our bending & forming capabilities

Min lead time

Bend angle tolerance

Edge to edge cut tolerances

Bend to edge tolerance

Maximum flat size

Minimum flat size

Material thickness

Min flange length (depending on material thickness)

Max bend width (depending on material thickness)

Our tapping capabilities

Min lead time

Min material thickness

Max material thickness

Min thickness to bolt ratio

Min part size

Max part size

UNC thread sizes

| Tap | Hole size |

|---|---|

| 0-80 UNC | 1.2mm |

| 1-64 UNC | 1.5mm |

| 2-56 UNC | 1.8mm |

| 4-40 UNC | 2.3mm |

| 5-40 UNC | 2.6mm |

| 6-32 UNC | 3mm |

| 8-32 UNC | 3.5mm |

| 10-24 UNC | 3.8mm |

| 1/4-20 UNC | 5.1mm |

| 5/16-18 UNC | 6.5mm |

| 3/8-16 UNC | 8mm |

| 7/16-14 UNC | 9.3mm |

| 1/2-13 UNC | 10.7mm |

| 9/16-12 UNC | 12.3mm |

| 5/8-11 UNC | 13.5mm |

| 3/4-10 UNC | 16.7mm |

UNF thread sizes

| Tap | Hole size |

|---|---|

| 2-64 UNF | 1.8mm |

| 4-48 UNF | 2.4mm |

| 5-44 UNF | 2.6mm |

| 6-40 UNF | 2.9mm |

| 8-36 UNF | 3.5mm |

| 10-32 UNF | 4mm |

| 1/4-28 UNF | 5.4mm |

| 5/16-24 UNF | 6.9mm |

| 3/8-24 UNF | 8.4mm |

| 7/16-20 UNF | 9.9mm |

| 1/2-20 UNF | 11.5mm |

| 9/16-18 UNF | 12.7mm |

| 5/8-18 UNF | 14.3mm |

| 3/4-16 UNF | 17.5mm |

Metric thread sizes

| Tap | Hole size |

|---|---|

| M2 x 0.4 | 1.6mm |

| M2.5 x 0.45 | 2.05mm |

| M3 x 0.5 | 2.5mm |

| M4 x 0.7 | 3.3mm |

| M5 x 0.8 | 4.2mm |

| M6 x 1.0 | 5mm |

| M8 x 1.25 | 6.7mm |

| M10 x 1.5 | 8.5mm |

| M12 x 1.75 | 10.2mm |

Countersinking capabilities

Min lead time

Min part size

Max part size

Min material thickness

Max material thickness

Angle

Minimum minor diameter

Maximum major diameter

PEM hardware inserts

Min lead time

Min part size

Max part size

Min material thickness

Max material thickness

Available hardware

| Flush stud | |

|---|---|

| Metric | UNC |

| M3 x 0.5, 6mm | 4-40, .250" |

| M3 x 0.5, 8mm | 4-40, .375" |

| M3 x 0.5, 10mm | 4-40, .500" |

| M3 x 0.5, 12mm | 4.40, .625" |

| M4 x 0.7, 6mm | 6-32, .250" |

| M4 x 0.7, 8mm | 6-32, .375" |

| M4 x 0.7, 10mm | 6-32, .500" |

| M4 x 0.7, 12mm | 6-32, .625" |

| M5 x 0.8, 8mm | 8-32, .250" |

| M5 x 0.8, 10mm | 8-32, .375" |

| M5 x 0.8, 12mm | 8-32, .500" |

| M6 x 1.0, 12mm | 8-32, .625" |

| M6 x 1.0, 20mm | 10-32, .375" |

| M8 x 1.25, 12mm | 10-32, .500" |

| M8 x 1.25, 25mm | 1/4-20, .375" |

| 10-32, .750" | |

| 1/4-20, .500" | |

| 1/4-20, .750" | |

| 1/4-20, 1.000" | |

| Flush standoff | |

|---|---|

| Metric | UNC |

| M3 x 0.5, 6mm | 4-40, .250" |

| M3 x 0.5, 10mm | 4-40, .375" |

| M3 x 0.5, 12mm | 4-40, .500" |

| M4 x 0.7, 6mm | 6-32, .250" |

| M4 x 0.7, 10mm | 6-32, .375" |

| M4 x 0.7, 12mm | 6-32, .500" |

| M5 x 0.8, 6mm | 6-32, .625" |

| M5 x 0.8, 10mm | 8-32, .250" |

| M5 x 0.8, 12mm | 8-32, .375" |

| 8-32, .500" | |

| 10-32, .250" | |

| 10-32, .375" | |

| 10-32, .500" | |

| Nuts | |

|---|---|

| Metric | UNC |

| M3 x 0.5 | 4-40 |

| M4 x 0.7 | 6-32 |

| M5 x 0.8 | 8-32 |

| M6 x 1.0 | 10-32 |

| M8 x 1.25 | 1/4-20 |

| 5/16-18 | |

| 3/8-16 | |

Our dimple forming capabilities

Min lead time

Min part size

Max part size

Min dimple size

Max dimple size

Min material thickness

Max material thickness

Sheet metal finishing

What is sheet metal fabrication?

The term 'sheet metal fabrication' refers to the numerous manufacturing methods used with sheet metals, including laser cutting, bending, welding, and forming.

Metal is an extremely versatile material thanks to its ability to be melted down, reformed, manipulated, high strength, high-temperature conductivity, electrical conductivity, and its alloying capabilities. Once extracted from ore, metal can be directly formed into different shapes at a foundry, including ingots, cylinders, and sheets. Of these, sheet metal is one of the more versatile forms as it is easy to transport, can be directly machined by tools, is suitable for numerous different manufacturing techniques, and is easier to handle.

Examples of manufacturing techniques that sheet metal can undergo include stamping, molding, laser cutting, plasma cutting, milling, drilling, cutting, shearing, and bending. Furthermore, constructive techniques, such as welding, can then be used to turn flat sheets of metal into complex 3D shapes, and this sees sheet metals used for all kinds of industries, including automotive, aerospace, medical, and consumer electronics.

Ponoko is a laser cutting company that can work with sheet metals to fabricate custom 2D parts. While we do not offer welding or other forming services, we do offer metal bending, burnishing, and polishing to provide market-ready sheet metal parts. Furthermore, we can manufacture and deliver these parts same-day for customers in the Oakland Bay Area, and next day for customers in the Mainland US.

Sheet metal fabrication materials

We offer many different sheet metal options, including stainless steel, aluminum, brass, and copper, all of which are available in various grades. Stainless steel is ideal for creating structural components and enclosures that need to resist corrosion and oxidation. Aluminum is suitable for use in portable applications where weight is a concern, as well as applications that need to resist oxidation. Brass is an excellent material for low-friction contact applications such as motor contacts and gears, and also for artistic applications such as decals and trimming. Copper is suitable for electrical applications that need high electrical and thermal conductivity, such as copper bus bars, heat sinks, and connectors.

We also accept custom sheet metal stock which is useful for engineers where material selection is critical. So long as the sheet metal is laser-safe (i.e., suitable for laser cutting), simply let us know what material you specifically require, and our engineers will help find suitable stock for your sheet metal fabricated parts.

The future of sheet metal fabrication - software-driven manufacturing

Under traditional manufacturing processes, getting a custom sheet metal part fabricated can be an extremely challenging task. Not only do designs need to be checked routinely for manufacturing viability, but suitable manufacturing files for parts need to be generated, and these files can vary between different machining stations.

In addition to this, trying to move designs from a prototype to a full-scale production part can introduce numerous difficulties, including material sourcing and changes in tolerance. This is also problematic when trying to get accurate pricing, as most manufacturers will generate unique quotes for every order that vary depending on which direction the wind blows.

Our cloud manufacturing services not only simplify the design phase of sheet metal fabricated parts, but also standardise the pricing so that instant quotes can be delivered to you. In just a few minutes, sheet fabricated designs, prototypes or full-scale production runs, can be uploaded to our cloud-based software for an instant quotation which will provide you with numerous options for material, thickness, complexity, and quantity. Once paid, designs are immediately sent to our production facilities, whereby designs are matched to specific cutting stations to maximize manufacturing efficiency.

Our software-based tools also allow engineers to move their prototypes to full-scale production designs in just a few clicks without the need to make any adjustments whatsoever. The only change that you need to make is to enter the quantity which you need, and the instant quote tool will provide you with the final price, not an estimate, that can be paid immediately to get our manufacturing sites fired up.

How much does sheet metal fabrication cost?

The cost of custom sheet metal fabrication depends on the material chosen, the size of the part being fabricated, the complexity of that part, and any additional features and/or services needed for that part. For example, cold roll carbon steel is almost half the price of aluminum, meaning that parts, meaning that choosing steel over aluminum can see a price saving of 50%. Smaller parts are cheaper to produce compared to bigger parts due to the less material used, but complex features that take time to cut will result in more machine time, and thereby increasing the cost of manufacture.

Engraving allows for parts to have graphics and text etched into their surface, but this is a slow process (especially for bitmap graphics), and so the more engraving area a part has, the more expensive that part will be. Additional services such as burnishing, polishing, and bending require numerous manufacturing steps, which incurs extra manufacturing costs. Simply put, doing less to a part will result in a part being cheaper.

Another major factor in the cost of parts is the order quantity. Ordering larger volumes of a part results in a significant decrease in cost per unit thanks to economies-of-scale, and Ponoko offers discounts of up to 93% for order quantities exceeding 10,000.

Precision sheet metal fabrication manufacturing, at speed

When it comes to manufacturing, it is essential that the process is as economical as possible, and this is usually realised through high-speed manufacturing at scale. But as important as production speed is, it is also equally important to ensure that quality and precision is never sacrificed. This is why finding the right balance between speed, precision, and price is by far the most important role of a manufacturer.

As a manufacturer, we have developed and refined our sheet metal fabrication capabilities over the years to provide engineers with high-quality sheet metal fabrication, regardless of the order size or part complexity. Sheet metal prototypes can be ordered, manufactured, and delivered on the very same day for customers in the Oakland Bay Area, and the precision and quality of prototype parts is identical to those of market-ready production parts.

Our ability to maintain precision across all parts manufactured is demonstrated in our 99.7% precision part quality record, over 2 million parts for 33,000+ customers. Therefore, it doesn’t matter whether a part is ordered today, tomorrow, or next year; our level of precision will ensure that each and every part is indistinguishable from each other, including material quality, tensile strength, weight, and size.

What can sheet metal fabrication be used for?

One of the best features of sheet metal fabrication is that it can be used for making just about any 2D part you can think of. As our sheet metal fabrication service uses high-powered lasers, parts do not require breakout tabs, meaning that perfect 2D shapes can be made that include cut-outs.

Brackets and fixtures are commonly made using sheet metal fabrication processes as these can be quickly cut out from strong materials such as steel and brass, bent to shape, and made at scale. The lack of tooling and molds makes this particularly useful for custom brackets in applications needing low order volumes. This also applies to fittings and washers which are also able to take advantage of sheet metal fabrication processes.

Faceplates and enclosures are other examples of a part that commonly uses sheet metal fabrication processes. The ability to make internal cutouts enables faceplates to accommodate hardware such as displays and buttons, and the engraving capabilities of our sheet metal fabrication also allow for graphical elements to be integrated into designs. This is useful for situations where instructions and other important text is needed on a faceplate.

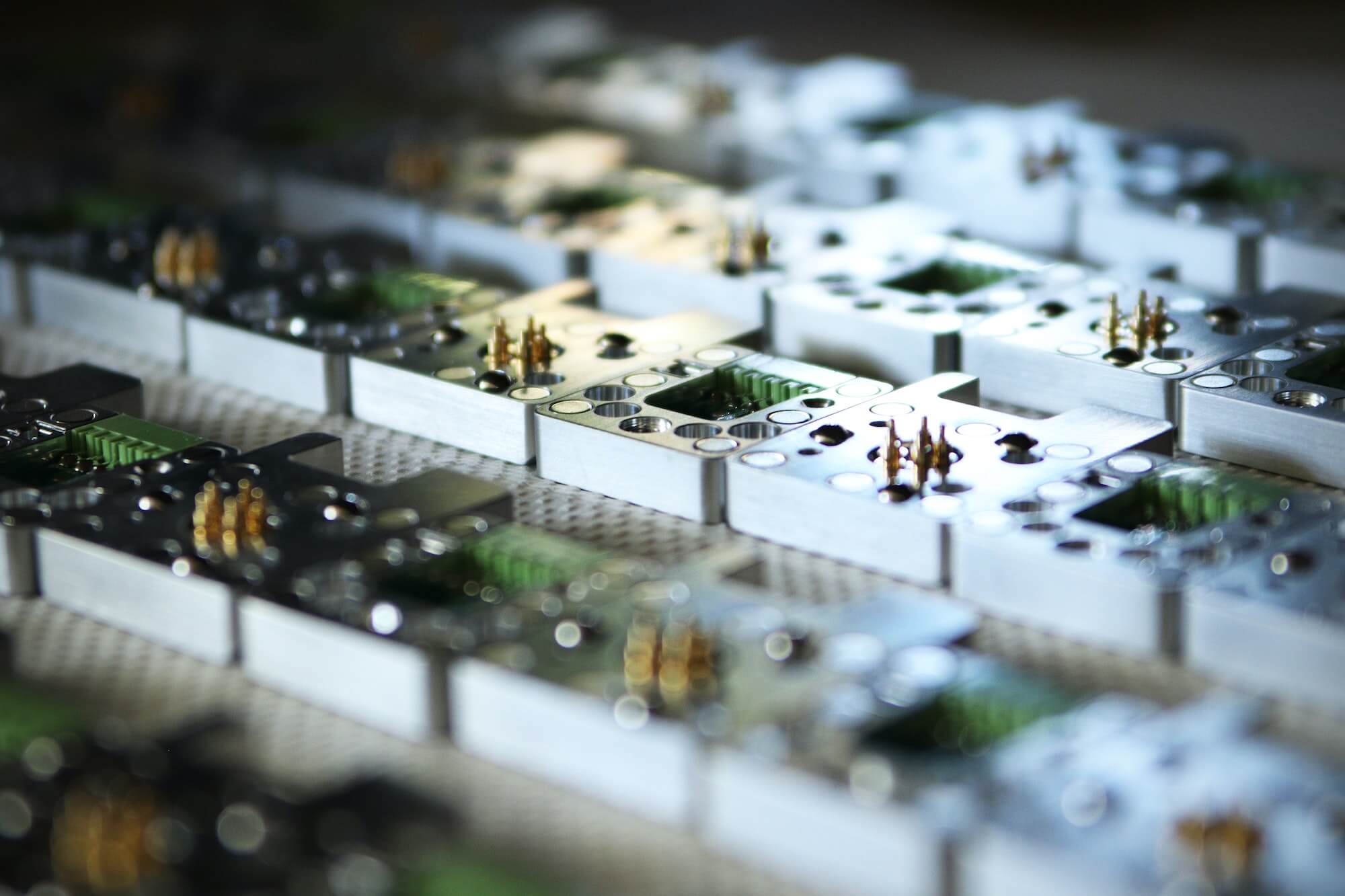

For applications in electronics, sheet metal fabrication is also ideal for manufacturing RF shields that are used to control EMI. As most commercial and industrial electronics need to adhere to very strict emission regulations, a quick solution for engineers can be to cage their devices in Faraday cages, but while off-the-shelf solutions exist, they can often be basic in design. A custom EMI shield using our fabrication services can create custom shields to fit any PCB shape.

Metals such as copper can be used with our sheet metal fabrication services, and this is ideal for manufacturing high-current bus bars. Thanks to the high electrical and thermal conductivity of copper, such bus bars are able to minimize power loss while simultaneously maintaining a low temperature.

Electrical enclosures

In many cases, electronic devices will use enclosures made from plastic due to its ability to provide electrical insulation, resist corrosion, and significantly low costs when manufactured in bulk. But in applications involving high voltages, or environments where impacts can be expected, sheet metal fabrication is a far suitable choice. The ability to ground the case provides an additional layer of safety (whereby live wires coming into contact with grounded cases will result in a GFCI trip), while the structural properties offered by sheet metals enable them to take significant impacts from people, other equipment, and even drops. In other cases, sheet metals can provide a professional finish, something which is commonly found in the electronics consumer industry in laptop enclosures.

Bus bars

Applications that involve large voltages and currents can often struggle to use PCBs for distributing power due to the high resistance of thin PCB layers. Adding additional tinning to PCB power traces is one option for increasing power capabilities, but this will leave traces exposed with no protection against arcing or accidental short circuits. Instead, engineers can opt to use sheet metals as bus bars which can be cut to shape to fit an enclosure or mounting. This gives engineers the advantage of being able to create a design that is perfectly optimised (therefore minimising resistance in the bus bars). Once installed, these bus bars can be insulated with a conformal coating to prevent arcing and accidental shorts, while insulated mechanical fixtures can provide the bus bars with structural stability.

Brackets

In applications that involve unique mechanical setups, having custom brackets and mountings can provide engineers with a high degree of freedom, but manufacturing 3D metal shapes using CNC milling and/or casting is an extremely expensive option due to the need for long tooling times and molds. Instead, sheet metal fabrication is by far one of the better options thanks to the low cost in sheet metal cutting and the ability to have sheet metal parts bent. Furthermore, the ability to support cut-outs in sheet metal parts (due to the use of fibre lasers), enables brackets to have any kind of hole required. Examples of where such brackets can be crucial include electronic consumer devices, mechanical fixtures, automotive vehicles, and medical devices.

Why you can trust Ponoko with your sheet metal fabricated parts

No matter if a single prototype or ten thousand market-ready parts are being ordered, having trust in your manufacturer is absolutely essential. Parts that are going through the prototyping stage will likely involve intellectual property and trade secrets that need to be kept away from the public eye, and production parts will need to have a great deal of precision so that they are consistent.

Having over ten years of experience in the field of sheet metal fabrication and with over 2 million parts manufactured, our 33,000+ customers continue to use our fabrication services because they know that every part they order will conform to our strict set of capabilities. At the same time, we provide 365-day guarantees on all parts, no matter the order size, meaning that engineers can remain confident in the longevity of their parts.

Sheet metal fabrication FAQ

What is sheet metal fabrication?

What metals can be sheet fabricated?

What machining methods exist for sheet fabrication?

What are the benefits of laser sheet metal fabrication?

What disadvantages does laser sheet metal fabrication present?

What applications can sheet metal fabrication be used in?

What is the sheet metal fabrication process?

What should be avoided when creating sheet metal parts?

What accuracy and precision does Ponoko offer on sheet metal parts?

Need something else? Check out our other manufacturing services!

Sheet metal fabrication is excellent for making 2D metal shapes, but not everything is made of metal! If you are looking for plastic, cardboard, or wood parts, check out our laser cutting service which offers over 250+ materials, or instead, if you need a 3D part with complex features, consider our range of 3D printing services, which includes FDM, SLA, and SLS printers. For those who are manufacturing products for the electronics industry, then check out our full PCB assembly service which combines PCB fabrication and PCB assembly into a single, easy-to-use service.

Order custom sheet metal fabricated parts from your laptop, delivered same day.*

From $50 for just 1 … 93% off for 10,000.