Laser engraving service - custom parts, delivered the day you order.*

On demand prototyping & production, same day from $50 for just 1. 93% off for 10,000.

"I am so impressed with @Ponoko Fantastic company!! Great customer service, lightning shipping, and beautiful work."

"We see this as the beginning of something huge"

Cloud manufacturing technologies to accelerate your hardware build.

Startups & enterprises rely on our cloud accelerated prototyping & production, to build the next great products.

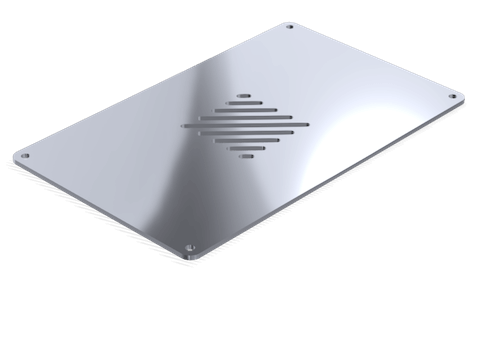

Sheet Metal Fabrication

- ±0.13mm Dimensional accuracy

- 3000x1500x25mm Max part size

- 15x15x0.4mm Min part size

- 1x1mm Min feature size

- ISO-9001, ITAR

- Same day Min lead time

Laser Cutting & Engraving

Sheet Metal Photochemical Machining

3D Printing

Injection Molding

Assembled Printed Circuit Boards

Custom laser engraved parts from $50 same-day quote & delivery

Ponoko offers laser engraving services for a wide range of materials. We offer laser engraving for two tone plastics for high contrast graphics, transparent plastics for edge lighting, and even metals. If you need to engrave your logo on a metal plate for the machine you're building, or some part marking text for your product packaging, you've come to the right place.

You design, we laser engrave: Ponoko provides the materials needed for the engraving process, allowing you to send in designs, and have your data plate, control panel, or faceplate both laser cut in the exact shape you require and laser engraved to have the features you need in the highest detail possible.

Ponoko's laser engraving services are available for anything from a single unit to a mass production lot purchase. So whether you need a single engraved sign or a batch of laser engraved enclosures, Ponoko has you covered!

Custom laser engraved parts delivered same day (or money back).

What is laser engraving?

Laser engraving is the process of marking a surface with the use of a laser beam, and is ideal for creating text and graphics during the laser cutting process.

While a laser cutter uses a laser beam to cut entirely through a piece of material, laser engraving only cuts at the surface of a material so that a permanent mark is left. Even though some material is removed, the depth of the cut is shallow enough that the mechanical properties of the material are virtually untouched to the point where two identical parts with one having laser engraved marks would be indistinguishable from a mechanical point of view.

To achieve laser engraving, a laser cutter has two options; either the output power of the laser can be reduced, or the machine can speed up each axis so the laser beam doesn't spend too much time in any one area. While speeding up the machine does result in a faster engraving, it can introduce issues with accuracy, and reducing the laser power can see engravings take a very long time to produce. As such, laser cutters often deploy a mix of both tactics by reducing the laser power and speeding up the individual axis.

When engraving patterns, it is important to understand the difference between vector and raster images. A vector image is one that consists of mathematical expressions describing curves and lines, while a raster image consists of an array of numbers each representing a pixel. Vector images are the easiest for laser cutters to work with as laser cutters naturally work with vectors, while raster images can create complex designs (such as photographs). At the same time, vector images are challenging to use on detailed images while raster images can take a very long time to produce (as they are engraved in a similar fashion to old dot matrix printers).

Ponoko is a laser cutting company that supports laser engraving on almost all 200+ materials stocked, and uploaded designs can combine both laser cutting and laser engraving lines. To keep the two different jobs separate, designs merely need to use two different colors to indicate which lines are for cutting, and which are for engraving.

Why use laser engraving?

What laser technologies support laser engraving?

How does laser engraving differ from mechanical engraving?

Ponoko provides 200+ materials ready to be laser engraved online.

When choosing a material for a laser-engraved part, it is imperative that only laser-safe materials are used, otherwise, toxic gasses can be released, the laser cutter can break, or the part can melt. Ponoko stocks over 200+ engineered materials that have been carefully curated to ensure they are laser safe. Furthermore, all materials stocked have been carefully categorized and documented to provide all the engineering data needed such as tensile strength, electrical conductivity, and density. During the ordering stage, different materials can be compared, and all materials are available regardless of the order quantity.

Ponoko delivers custom laser engraved parts, same day -- from $50 for just one.

What is laser etching?

Despite their similarities, laser etching and laser engraving are different in that etching deforms the surface of a part while engraving physically removes a channel of material (albeit very shallow).

As laser etching merely deforms the very top surface of a part, it is significantly faster than laser etching and is therefore ideal for parts being mass produced. Furthermore, the lower energy requirements of laser etching also reduces operational costs, and this complements mass production well.

However, laser etching suffers from the disadvantage that it can be removed as material isn't being removed. As such, laser etching is ideal for serial numbers and tracking numbers for internal manufacturing processes, but should not be used for security identifiers or graphics that expect to be used in abrasive environments. Finally, laser etched designs are not as visible as laser engraved parts, and this is particularly problematic on shiny materials such as metal.

While Ponoko doesn't offer laser etching services, our photomechanical etching process can be used for creating parts that require extreme precision. Instead of using a laser cutter to remove material, a photoresist is used to protect areas of importance on a part, while unprotected areas are chemically etched away. Currently, this process is only available for copper, and is ideal for creating heat sinks, gears, actuators, and intricate artistic components.

Will laser engraved features wear off?

How much does it cost to laser engrave something?

Is laser engraving done on a different machine than laser cutting?

Start from just 1 laser engraved part, delivered same day.

Scale to 10,000 parts, at 93% off.

What materials can be engraved?

Just like how laser cutters can only be used on laser-safe materials, only materials that are laser-safe can be engraved.

Even though laser cutters have the capability to cut just about any material (assuming it has the energy to do so), some materials cannot be cut with a laser due to the release of toxic gasses, particulates, or reactivity. In the case of toxic gasses, materials such as PVC can very easily be cut with a CO2 laser, but the intense heat releases chlorine gas that is not only toxic to equipment, but to those nearby and the wider environment. Other materials can release particulates that can buildup on sensitive components such as reflectors which degrade the performance of the laser cutter. Finally, highly reflective materials can be outright difficult to cut as they reflect the vast majority of the laser energy, and this can reflect back into the laser cutter and damage it.

Despite the fact that laser engraving doesn't cut all the way through a part, it still vaporises the target material, and therefore has the potential to release said toxic gasses and/or particulates. Another challenge faced by laser cutters is that they cannot engrave onto uneven surfaces such as fabrics. However, this is due to the fact that fabrics can unweave themselves and fall apart which would outright destroy any pattern engraved onto them (not that it's impossible, but unsuitable for soft loose materials such as felt).

What applications can engraving be used in?

What disadvantages does laser engraving have?

Is a laser engraver worth buying?

Trusted by 35,000+ founders, CEOs, engineers, designers & scientists.

Order laser cut custom parts from your laptop, delivered same day.*

From $50 for just 1. 93% off for 10,000.