When Standard Acrylic Is Too Brittle, Use This Latest Addition

Acrylic is terrific for so many projects; that’s why it’s the number-one material for laser cutting. But as great as standard acrylic may be, sometimes it’s just too brittle for certain applications.

The solution? Impact modified acrylic, and it’s just been added to the USA catalog in 2mm thickness and to the NZ catalog in 3mm thickness.

Benefits Of Impact Modified Acrylic For Laser Cutting

We get asked all the time if polycarbonate can be laser cut. While polycarbonate has its place in the manufacturing realm, it’s best shaped via other types of machines because it isn’t a good material for laser cutting.

In fact, when heated by the laser, polycarbonate emits yellow smoke and the cut edges have nasty brown burns and become pitted. No good. (Read all about our experiment trying to laser cut polycarbonate here. #epicfail)

A better (and safer) alternative is impact modified acrylic. It’s stronger than traditional acrylic yet laser cuts just as beautifully. Check out this supplier testing for strength comparison using the Izod testing scale:

Polycarbonate = 12

Standard Acrylic = 0.4

2mm 40% Impact Modified Acrylic – USA = 2.4

3mm 70% Impact Modified Acrylic – NZ = 3.2

Impact modified acrylic is also preferable to polycarbonate because the latter is more prone to scratching and will yellow over time when exposed to sunlight. And since polycarbonate diffuses light differently, it has less overall clarity than acrylic. Thus, if durability is factor yet you don’t want your designs to lose color or clarity due to UV exposure, impact modified acrylic is the natural choice.

Impact Modified Acrylic For Engineering Projects

When building engineering projects, using impact modified acrylic results in a more substantial, stronger box or panel that can withstand more stress than standard acrylic. So what can be made with this new material? Here are some examples we tried:

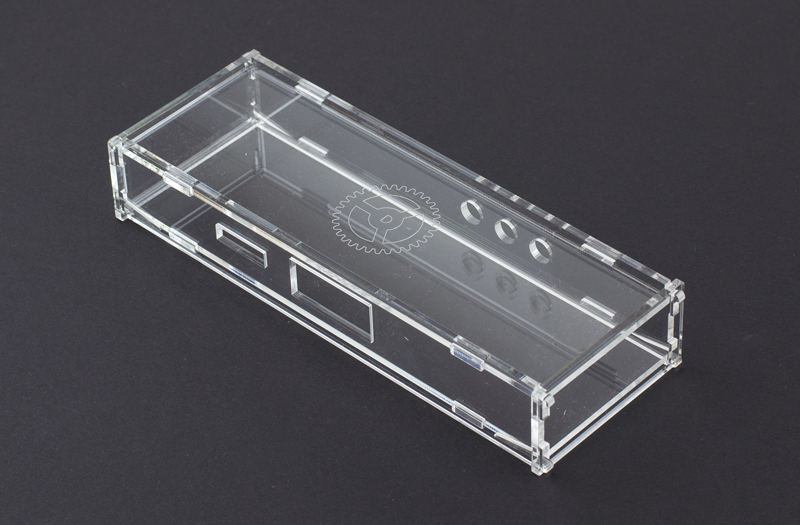

When builds need superior protection, why not design electronics enclosures from impact modified acrylic? You’ll have the strength required to protect the components while having a slick case for displaying them. #winning!

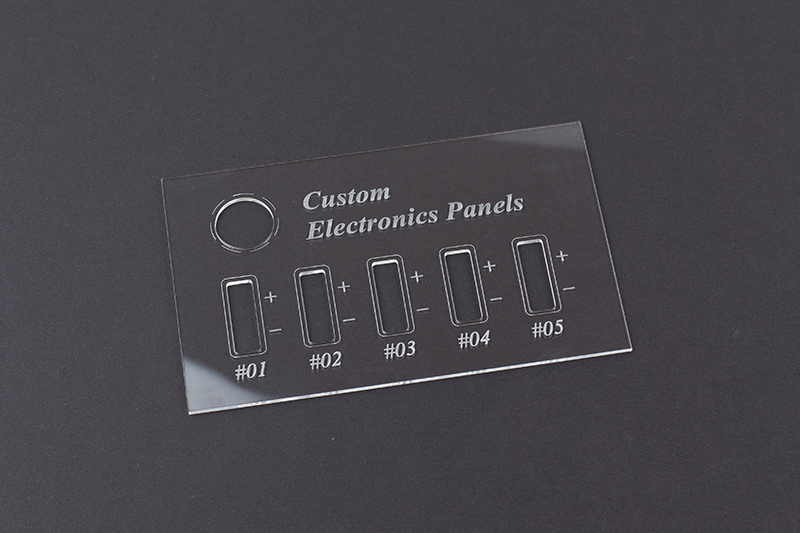

Don’t need an entire enclosure? Custom panels also provide durability and protect internal components from impact.

Impact modified acrylic’s strength is a plus when designing gears, and laser cutting will ensure a consistent fit—and important consideration if you’re making a product to sell.

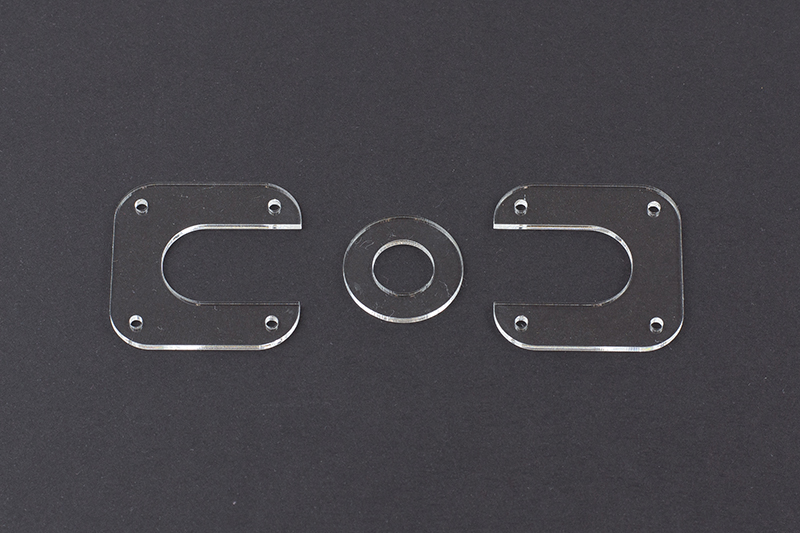

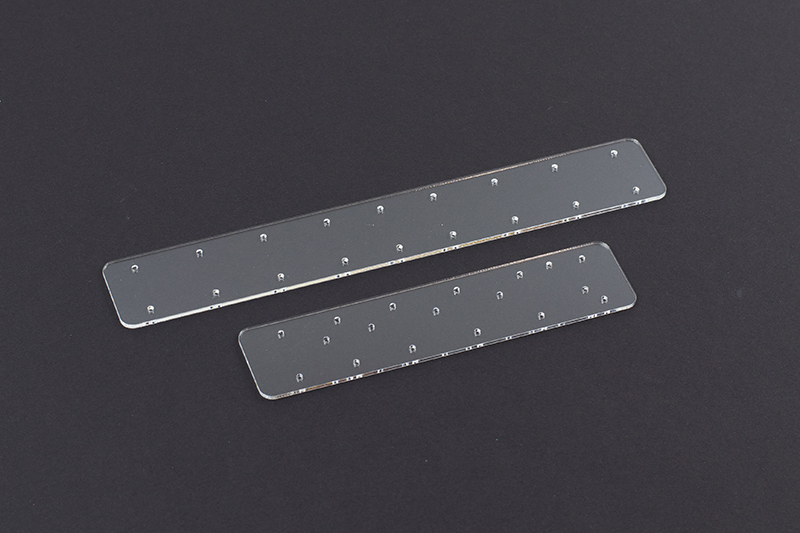

See those screw holes? These types of component parts are meant to be fastened together with screws, which means force must be applied when used. This force could potentially break standard acrylic; impact modified acrylic to the rescue!

When mounting electronic components to acrylic panels to hold them in place, it’s essential to have a strong base like this example in order for your designs to last longer.

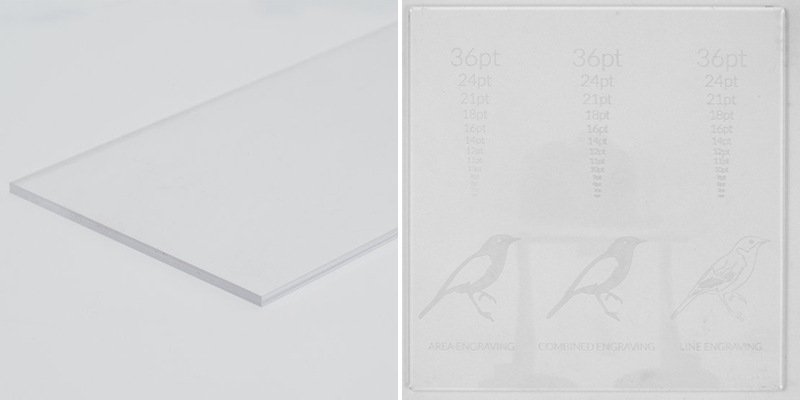

Impact Modified Acrylic For Signage

Since impact modified acrylic has great clarity and doesn’t yellow in the sun, it’s ideal for making signs. Here’s a simple example using line engraving for the logo and area engraving for the text.

You can also cut out individual letters to create signage. Just make sure to have a straightedge and a level for installation to ensure alignment!

Now Available: Impact Modified Acrylic

Impact modified acrylic has high impact strength yet is lightweight and easy to thermoform. Its good gauge tolerance helps parts fit together, and its high clarity and light transmission combined with weather- and UV-resistance make it ideal for projects that will be exposed the elements.

If your laser cutter project needs durability, USA-based makers can find all the details on 2mm 40% impact modified acrylic here or snatch up a sample here. For those in NZ where the sheet is 3mm thick and 70% impact modified, read all about it here and get a sample here to see it for yourself.

Maker Tip: As an impact modified acrylic, this material contains a small amount of polymer that is similar to rubber to give it extra strength and flexibility. As a result, impact modified acrylics are slightly more supple and melt a bit more during cutting than standard acrylics. Therefore, when designing for this material, make sure the small details for cutting are a bit bigger than they would normally be constructed on standard acrylics.

What Will You Laser Cut With Impact Modified Acrylic?

With impact modified acrylic added to both the USA and NZ materials lineup, what will you make? Will you try your hand at electronics enclosures or signage like we did, or will you branch out into robots or some other kind of engineering build? Whatever you decide to make, share your ideas in the comments below. We’d love to hear about it!