Maker Needlessly Complex’s Exposed Gear Clocks Make Time Keeping Easy—And Oh So Fun

As a maker, how many times do you see something really cool and think, “I could totally make that myself…”? Happens all the time, right?

But how often do you actually make it? Ah, there’s the rub.

Like you, Henry Stafford has seen his share of interesting products to make, such as exposed gear bike chain clocks he often stumbles upon while surfing the web. The difference this time was that not only did he start making these kinds of timing chain clocks, but based on lots of great feedback he also launched Needlessly Complex and began selling them, too. And he credits Ponoko with helping him get past the idea phase and into full-blown production mode. Here’s his story.

Finding Inspiration

A sales engineer for a network security company, Henry spends his days making sure that only the good 1s and 0s get from Point A to Point B. However, he actually has a mechanical engineering degree that’s not really been put to good use…until now.

So how did he begin making and selling a line of exposed gear bike chain clocks? It was completely accidental.

“I saw a post about an artsy clock that used a chain to tell time. It was pretty amazing, but it was $2,000+,” he explains. “My usual thinking when I can’t afford something is, ‘Well, that looks easy, I could make that.’ I went through several failed prototypes before coming up with a basic version made from small sprockets and motors that I could buy. I tried a few 3D printing services but wasn’t happy with the precision or the look of the parts; they had a very cheap look and feel. During my research for an alternative, I discovered Ponoko and laser cutting.”

Gearing Up For Clockmaking

After designing and ordering a few simple parts and then realizing how precise the laser cutting was, Henry moved on to creating more complicated parts such as gears and drivetrains for his exposed gear bike chain clocks.

“I started pretty small with just a bare-bones version, but I was hooked on thinking up more complex ways to transfer motion from the motors to the final driveshaft,” he explains.

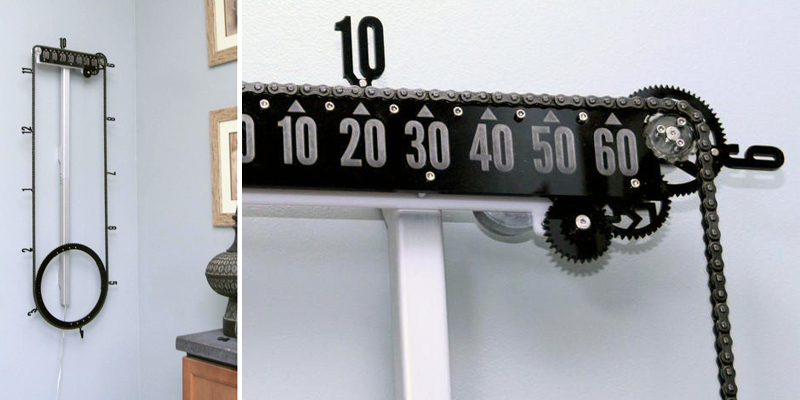

With The Slider, Henry developed a way for this clock to display both the hour and minute by having the current hour numeral move across the minute divisions as time passes by. The lower ring rotates along with the chain + keeps the chain in place.

But what if you want more cogs than that? Then Lotsa Cogs is the exposed gear clock for you. For this design, Henry combines an actual bicycle chain and a rear gear set with laser cut acrylic numerals and motor mounts. Add industrial synchronous A/C motors, and you’ve got an accurate time-keeping machine.

But Henry’s most popular item, by a large margin, is the Dual Chain Clock with a visible planetary gear drive. Every part of the mechanism is required for it to work, but the thing as a whole is more complicated than it needs to be—thus, needlessly complex!

There are two separate roller chains with laser cut numerals, one that displays the hour and one for the minutes. Each number chain is geared so that the current time can be read as the numbers travel over the top sprocket. It also features a smaller chain and sprockets as part of the drive chain, along with laser cut gears and other elements.

“I use white acrylic for the main body where the gears are attached so that the dark grey tint gears really stand out,” Henry says. “Some components are clear so the mechanism behind it can be seen as well. I chose acrylic because of the very clean lines that it gives, and it’s modern vibe. Also, I can easily cut threads into the acrylic, and it holds small bolts and screws very well.”

Looking for something a bit bigger? The Biggest One is a scaled-up version of the chain clock that uses a 5/8 inch link chain and features larger numerals to match. Even though it’s larger, this clock is also silent running thanks to it’s slow pace and bearing-supported main drive shaft.

Working With Ponoko

When searching for laser cutting services, what initially attracted Henry to Ponoko? “By a large margin, it was the simple workflow and automation,” he says. “I can upload a file using Ponoko’s templates, get an instant price quote and submit my order in a few minutes. Other services require file formats that are non-trivial to produce (unless one has very expensive/complicated software) and/or they don’t have the material selection that Ponoko does.”

Once he started laser cutting, there was no going back. “As somebody who is used to woodworking, being able to have sub-millimeter precision is just astounding,” Henry says. “There’s no other way I could cut gear teeth or have them aligned correctly without this level of precision.”

What making and cost savings tips does he have for other engineers and designers? “If possible when prototyping, include multiple versions of your design in one order/sheet. It’s cheaper to ‘waste’ several versions all at once than it is to refine and submit a new order numerous times. Also, combine the edges of your parts [nesting] when possible. There’s no sense in cutting out two squares when you can just join them together into a rectangle and then cut it in half.”

Finding Sales Success In A Digital World

Henry says that he really enjoys coming up with new ideas and trying to make them into “something useful, or at least something interesting.” And others agree. After posting pictures of the exposed gear bike chain clocks on a couple of social media platforms “just to show off,” he had multiple people asking where/how/if they could buy one.

The key to getting potential buyers’ attention, he says, is to be original and value your own work.

“There are a thousand people on Etsy sticking a cheap clock movement into just about anything circular and calling it a handmade clock,” Henry says. “In order to compete with the ‘me too’ sellers, you need something that really stands out.”

But just because you build it, people won’t necessarily come. Visibility, and ultimately sales, takes marketing, marketing and more marketing. “This has been the hardest thing for me,” Henry admits, “but I’ve had the most success/sales come from various blog posts mentioning my products and/or website. Don’t be afraid to ask people to give you a mention.”

Finally, having the right partners who deliver quality and reliability is at the foundation. “Without Ponoko’s service, I doubt I ever would have made it past the ‘Hmmm, I wonder how I could make that’ phase.”

2 Comments

Hi, Henry said that the key to getting potential buyers’ attention is to be original and value your own work. Do you agree that the price also matters?

Hi Shelly, yes a viable price point certainly matters when selling products. You’ll see at the top of the article, this was one of Henry’s starting points. Clocks he’d seen were just too costly, so he got to work making his own at a much better price. 🙂

Comments are closed.