Overview of Plastic Injection Molding

Plastic injection molding is a manufacturing technique that has transformed the production landscape, enabling the rapid creation of a wide range of plastic components. Its ability to handle large-scale manufacturing needs efficiently makes it a staple in various sectors, and its versatility in manufacturing complex shapes that would otherwise be challenging to create has revolutionized the way plastic parts are produced. The high precision and accuracy of plastic injection molding make it ideal for industries that require high-specification components, such as aerospace and precision electronics, where dimensional accuracy and smooth surface finishes are essential.

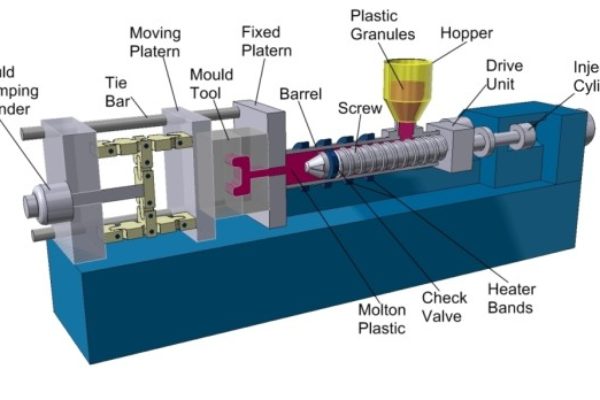

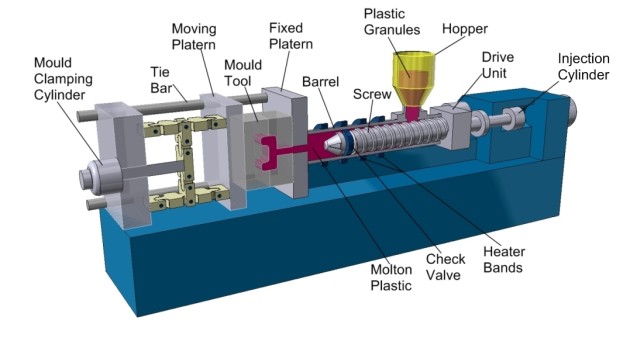

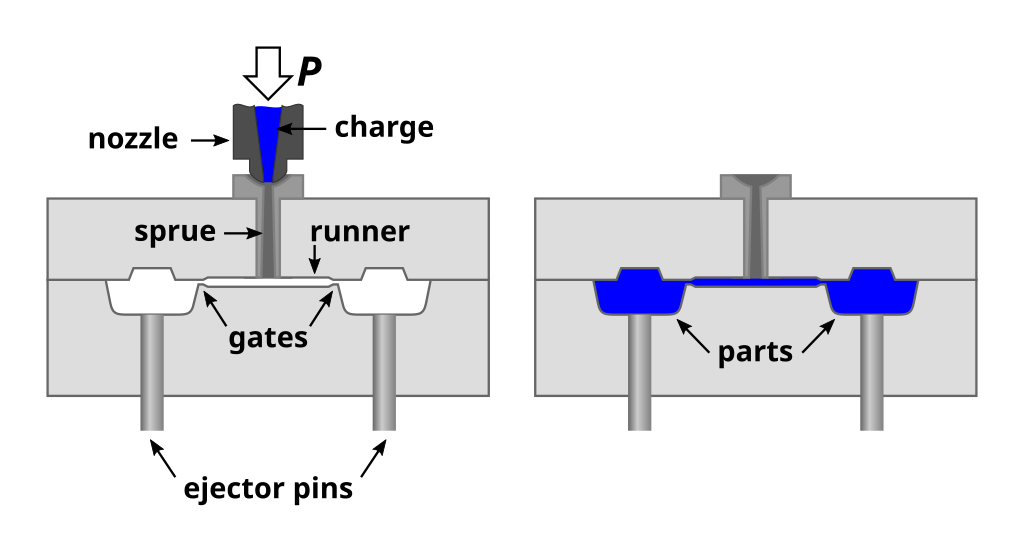

The process of plastic injection molding involves several critical steps, starting with the melting of plastic granules into a molten plastic that is then injected into a mold under high pressure. This high pressure is necessary to ensure complete filling of the mold, and this stage is also critical in determining the quality of the final part. After the injection phase, the plastic needs to cool and solidify, a process that must be carefully controlled to prevent defects such as warping or internal stresses, which can compromise the structural integrity of the part. Once the part has solidified, the mold is opened, and the part is ejected with great care to prevent damage to the newly formed plastic part.

One of the significant advantages of plastic injection molding is its ability to produce parts at scale. The high-speed manufacturing process and rapid part changeover enable industries that require large volumes of parts with uniform quality and precision. In fact, plastic injection molding is essential in industries such as automotive, where everything from dashboard buttons to bumpers are manufactured using this technique. The healthcare industry also heavily relies on plastic injection molding for the creation of durable medical devices and components that require high levels of accuracy and cleanliness.

The repeatability of the plastic injection molding process is another advantage that makes it a preferred method for manufacturing plastic parts. The ability to reproduce parts consistently ensures precision and accuracy in mass production, which is critical in industries that require parts to be interchangeable. Additionally, the cost of plastic injection molding parts decreases significantly as the mold design and creation costs are covered during the initial production run, and the cost savings only increase as the parts are produced in larger volumes. The durability of plastic parts also makes them an economical option for manufacturing, as they can withstand repeated manufacturing cycles without showing signs of wear and tear.

Plastic Injection Molding Materials

Plastic injection molding is a versatile manufacturing process that supports a wide range of materials each tailored to meet specific application needs. The ability to choose from various materials allows manufacturers to produce parts with optimal performance characteristics by selecting the most appropriate material. Materials such as ABS are ideal for parts requiring toughness and impact resistance while polypropylene is ideal for parts needing fatigue resistance, light weight, and flexibility. Polyethylene is ideal for parts needing chemical resistance while nylon is ideal for parts needing high strength and temperature resistance. Polycarbonate is ideal for parts needing transparency and incredible impact resistance.

Each material being considered brings unique characteristics to the table. Some materials offer better impact resistance while others offer greater flexibility. Heat tolerance is also an important factor with some materials being able to maintain their integrity and performance under thermal stress while others may begin to deform. Chemical resistance is also a critical factor with some materials being able to resist harsh environments that may otherwise cause degradation.

The selection of the right material is influenced by the specific requirements of the part including its function, the environment in which it will operate, and the level of durability needed. For example consumer products often require materials that are safe, aesthetically pleasing, and cost-effective while industrial applications may prioritize strength, thermal stability, and longevity.

Material choice also plays a significant role in the manufacturing process itself. The cost of a material can impact the overall cost of the part with some materials being more expensive than others. Production speed is also affected by material choice as some materials may cool or cure at different rates. Finally the finish of the final part can be influenced by material choice as some materials may require additional treatments or coatings to achieve the desired appearance and texture.

The decision on which material to use in plastic injection molding is critical and involves a careful assessment of the part’s requirements and the manufacturing process itself. The wide range of plastic materials available for injection molding allows for plastic parts to be engineered for performance and durability while also supporting mass production.

Overcoming Injection Molding Design Challenges

One of the primary challenges in injection molding design is managing the wall thickness of the parts. Uniform wall thickness ensures even cooling and material flow, which is crucial to preventing defects such as warping, sink marks, and voids. Warping occurs when different parts of the component cool and solidify at different rates, leading to distortions. Sink marks are depressions that appear when there isn’t enough material in the injection phase to compensate for shrinkage as the part cools. Voids are air pockets trapped inside the part, often resulting from uneven wall thickness. To mitigate these issues, designers must strategically plan the wall thickness to facilitate uniform cooling and material distribution.

Another critical aspect of the design process is the consideration of draft angles. Draft angles are slight tapers applied to the vertical faces of the parts, facilitating the easy ejection of the finished component from the mold. Without adequate draft angles, parts may stick to the mold, causing damage during ejection or requiring excessive force that could compromise the integrity of the part. The specific angle required depends on the depth of the mold and the surface finish of the molded part.

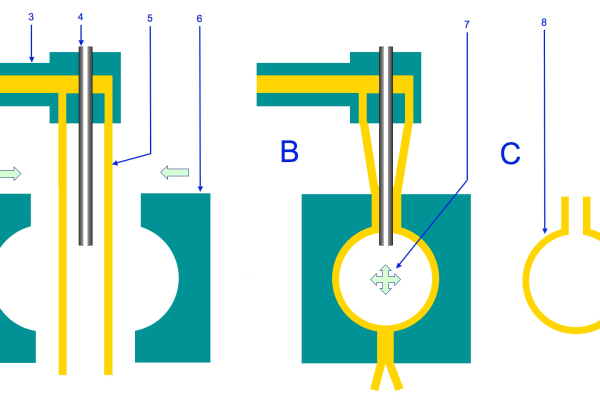

Gate placement also plays a pivotal role in the quality and aesthetics of the final product. The gate is the opening through which molten plastic enters the mold cavity, and its location, size, and shape can significantly influence the appearance and structural integrity of the part. Improper gate placement can lead to aesthetic flaws like visible lines and marks, as well as structural issues such as incomplete filling or excessive stress at certain points in the part. Strategic gate placement ensures a smooth flow of plastic into the mold, minimizing visual defects and enhancing the mechanical properties of the part.

Moreover, the design of parts with complex geometries, undercuts, and intricate details introduces additional challenges. Such features often require specialized mold designs with movable sections or advanced techniques like side actions, which can increase the complexity and cost of the mold. However, these features are sometimes necessary for the functionality or aesthetics of the part, necessitating a careful balance between design complexity and manufacturability.

To navigate these complexities, the use of simulation software has become increasingly prevalent in the industry. Simulation tools allow engineers to test and predict the performance of their designs before committing to production. This enables designers to make data-driven decisions and optimize their designs for manufacturability and cost-effectiveness.

The importance of material selection cannot be overstated. Material properties, such as tensile strength and density, affect the part’s ability to withstand stress and its mass. The flow properties of the material also impact the mold’s filling behavior and the final quality of the part. Engineers must carefully evaluate these factors when selecting materials for injection-molded parts.

The use of additives can also be critical in achieving the desired properties of the final part. Engineers can adjust the formulation of the plastic to enhance its performance characteristics, such as strength and durability, or to improve its machinability and compatibility with future processing stages. However, the use of additives must be carefully managed, as excessive levels can negatively impact the quality and cost of the part.

How Much Does a Plastic Injection Mold Cost?

The cost of a plastic injection mold is influenced by a variety of factors, making it a critical consideration in the manufacturing process.

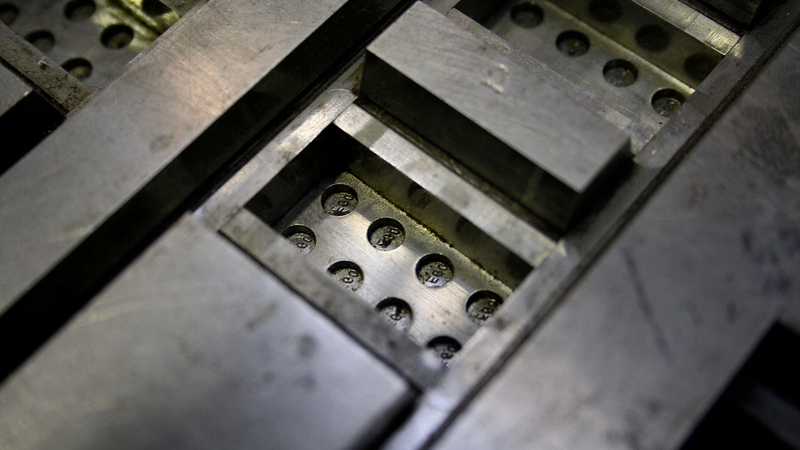

For example, a mold with intricate designs and features requires more precision engineering and detailed work, increasing the overall expense. The size of the mold also plays a significant role, with larger molds requiring more materials and sophisticated machinery, thereby increasing the cost.

The material used for the mold is another crucial factor, with basic aluminum molds being cheaper compared to steel molds due to the ease of machining and material durability. However, steel molds are preferred for high-volume production due to their durability and ability to maintain precision over an extended period, despite their higher cost. The price range for aluminum molds starts from $10,000, while steel molds can range from $50,000 to over $1 million.

The number of cavities in the mold also impacts the cost, with more cavities resulting in increased costs due to the need for a more complex mold design. However, this also leads to increased production efficiency, and thus the cost per part can decrease significantly with large-scale production. The precision required in the manufacturing of the mold also influences the cost, with high-precision molds requiring advanced technology and skilled labor, thereby increasing their cost. The expected lifespan of the mold is another factor to consider, with molds designed for limited use being cheaper compared to those intended for long-term use in mass production.

Additional features such as cooling channels and automated inserts can be incorporated into molds to enhance their functionality and efficiency, but these also increase the cost. The design process itself also contributes to the cost, with complex geometries and specialized features requiring expert knowledge and sophisticated design software.

Despite the high upfront costs associated with developing and manufacturing a plastic injection mold, the cost per part produced often decreases significantly with large-scale production, thanks to the ability of the injection molding process to produce parts quickly once the mold is made.

Cost Reduction Tips

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold to produce parts in large volumes. While effective, it can also be costly, particularly in terms of the initial setup and ongoing production expenses. However, there are several strategies that manufacturers can employ to reduce costs without sacrificing the quality of the final product.

One of the primary ways to decrease expenses is by simplifying the mold design. A mold with fewer cavities requires less material and is quicker to produce, making it a cost-effective option for small production runs or prototyping phases. This approach not only reduces the upfront investment but also speeds up the turnaround time, allowing companies to test and modify designs more efficiently before committing to large-scale production.

Another cost-saving measure is choosing aluminum over steel for the mold material. Aluminum molds are significantly cheaper and faster to manufacture than their steel counterparts. Although they are less durable and typically have a shorter lifespan, they are an excellent choice for projects that do not require a high volume of parts or the longevity that steel molds provide. This makes aluminum molds particularly appealing for prototyping and limited production runs, where the total number of cycles is relatively low.

Material waste reduction is also a crucial factor in lowering production costs. By optimizing the design of the part, such as reducing the thickness of the walls and simplifying the overall geometry, manufacturers can use less plastic per part. This not only cuts down on material costs but also reduces cycle times, as thinner walls cool more quickly. Additionally, these design optimizations can enhance the part’s functionality by removing unnecessary weight and material without compromising its integrity.

Combining multiple parts into a single mold is another effective strategy for cost reduction. This approach decreases the number of molds and machines required, thereby reducing labor and production expenses. It also minimizes the handling and assembly operations needed, further cutting down costs. By integrating several components into one complex mold, manufacturers can produce more intricate parts in fewer production cycles, effectively lowering the cost per part.

Finally, collaborating closely with an experienced injection molding partner can provide further cost-saving opportunities. A skilled partner can offer valuable insights into material selection, suggesting cheaper alternatives that meet the required specifications. They can also recommend design modifications that simplify production while maintaining part functionality. This collaborative approach ensures that all aspects of the production process are optimized for cost-efficiency while adhering to quality standards.

What Parts Are Good for Plastic Injection Molding?

Plastic injection molding is a manufacturing process that is highly adaptable and efficient, making it a popular choice for producing a wide range of plastic parts. The process involves melting plastic pellets and injecting the molten plastic into a mold under high pressure, and once cooled, the plastic can be repeatedly molded into the same shape with little variation. This precision and ability to produce parts at scale make plastic injection molding valuable in many industries, including consumer electronics, automotive, medical, and industrial sectors.

Consumer electronics, for example, rely on plastic injection molding to produce durable and lightweight parts such as cases and remote controls. The ability to create complex geometries and incorporate fine details enables plastic injection molding to produce parts that are both functional and aesthetically pleasing. The medical industry also benefits from the ability to create parts with high precision and accuracy, especially in the case of components that need to be biocompatible and non-toxic.

The automotive industry places similar demands on plastic injection molded parts, needing components to be durable and able to withstand various environments. The ability of plastic injection molding to create parts at scale also makes it ideal for industries that require replacement parts, such as automotive parts.

Industrial applications of plastic injection molding are also widespread, including the production of parts for machinery, equipment, and enclosures. The wide range of plastic materials available allows for parts to be engineered for specific environments, such as those exposed to chemicals or extreme temperatures.

Finally, plastic injection molding is also ideal for producing many everyday consumer products, including toys, kitchenware, and packaging materials. The ability to create parts cheaply and quickly enables plastic injection molding to be an economical choice for mass production, and the wide range of plastic materials available allows for parts to be engineered for specific applications.

Common Molding Defects

Despite its widespread use the process can be prone to several defects if not properly managed. Understanding these defects and how to address them is crucial for manufacturers to ensure high-quality production while minimizing waste and cost.

One common defect in injection molding is flash which occurs when excess material seeps out of the mold cavity forming thin protrusions along the parting line of the finished product. This issue often arises due to insufficient clamping force or misalignment of the mold halves. By carefully calibrating the clamping force and ensuring that the mold is perfectly aligned and closes correctly manufacturers can significantly reduce the occurrence of flash. Regular maintenance of the mold to prevent wear and tear is also essential in controlling this defect.

Another frequent issue is warpage whereby the molded parts distort or bend as they cool. This distortion is typically the result of uneven wall thickness in the design of the part or inconsistent cooling rates during the molding process. To combat warpage adjustments can be made in the design phase to ensure that walls are uniform. Additionally integrating uniform cooling channels within the mold can help in achieving more consistent cooling thereby reducing the likelihood of warpage.

Sink marks are yet another defect characterized by small depressions or voids on the surface of the molded parts. These occur primarily in thicker areas of the part where the outer shell cools and solidifies before the inner material leading to a collapse in surface. To prevent sink marks designers can optimize the geometry of the part to ensure even thickness and improve the cooling system within the mold to facilitate uniform cooling throughout the part.

Short shots are a defect whereby the mold cavity is not completely filled resulting in incomplete parts. This can happen due to insufficient injection pressure or inadequate material flow. Adjusting the injection parameters such as increasing the pressure or using a more fluid material can help fill the mold completely. Ensuring that the material is at the correct temperature for optimal flow is also critical in preventing short shots.

Lastly burn marks are another issue that can occur during the injection molding process. These marks are typically caused by trapped air in the mold that becomes superheated and burns the material. To reduce the risk of burn marks improving the venting of the mold is essential. This allows the trapped air to escape. Additionally optimizing the injection speed to ensure that the mold fills smoothly and at the right rate can also help minimize burn marks.

How to Get Started: Step-by-Step

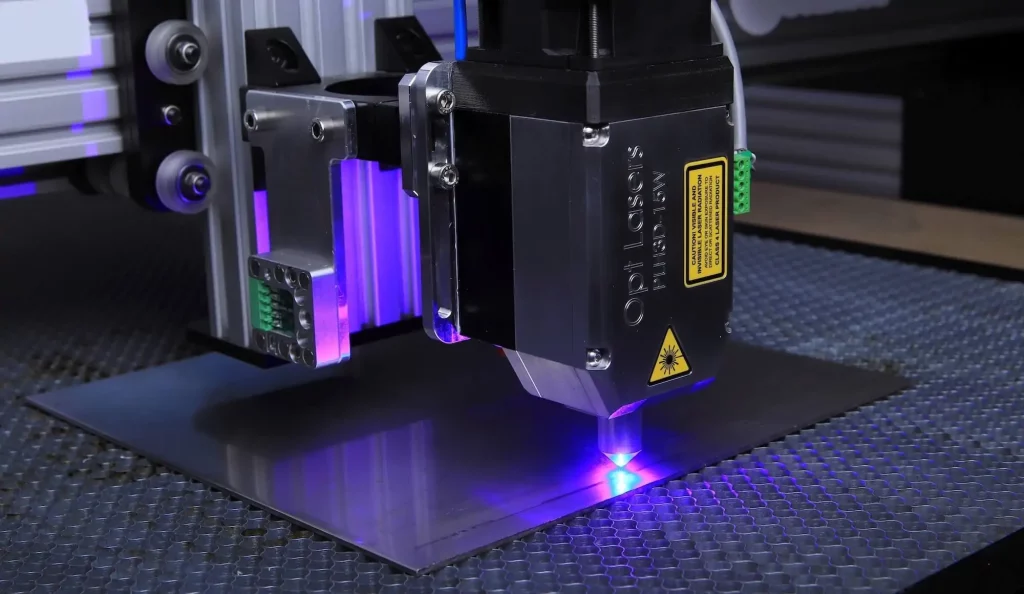

The process of manufacturing a part continues with the fabrication of the mold once the design and material have been confirmed. The mold is the core production asset, and its quality directly impacts the quality of the final parts. Therefore, it is essential to ensure that the mold is fabricated by a reputable company with expertise in mold design and manufacturing.

Such companies can provide valuable insights and guidance throughout the mold fabrication process, especially when custom molds are being ordered. The mold material should be carefully selected to ensure compatibility with the part material and to withstand repeated manufacturing cycles. Additionally, the mold material must retain its shape and structure under extreme temperatures without degrading or warping, and it should be durable enough to endure machine operation and maintenance.

After the mold is fabricated, the next step involves testing the mold to validate its performance. This testing phase is crucial for ensuring that the mold functions as expected and is ready for mass production. The testing process typically includes a physical inspection of the mold, a dimensional accuracy check, and a pressure test to verify the mold’s integrity. Any issues identified during this testing phase can be addressed before proceeding with mass production, thereby preventing costly retooling later on.

Once the mold passes all the tests, mass production of the part can begin through injection molding. The first few parts produced are often referred to as prototypes, and these are manufactured in smaller batches to assist with product validation and verification. The prototype parts can then be used for further testing, such as performance and stress testing, to ensure that the part meets all the requirements outlined in the initial project scope.

However, injection molding is a production method that is often difficult to scale down. This means that once prototypes are confirmed, it is usually more economical to move to mass production. As such, it is essential to have a clear understanding of market demand and the required production volume before initiating mass production. While a single injection-molded part can cost as little as $0.02, the molds themselves can cost thousands of dollars, so ordering too few parts can prove to be extremely costly.

The final step in the injection molding process involves quality control and packaging. The produced parts need to be inspected for any defects or imperfections, and those that do not meet the required standards must be removed from the production batch. The inspected parts can then be packaged and shipped to customers for use in their end products.

Key Takeaways

Plastic injection molding is a highly adaptable and efficient manufacturing process that is particularly suited for creating large quantities of precise components. The process involves melting plastic granules and injecting them under high pressure into a mold cavity where they cool and solidify into the final part. Due to its ability to produce complex shapes with great accuracy and repeatability, it is widely used in various industries including automotive, healthcare, and consumer electronics.

However, the selection of appropriate materials and the optimization of part design are critical steps in maximizing the effectiveness of the injection molding process. Different plastics offer distinct properties such as toughness, flexibility, and resistance to heat and chemicals, and the choice of material can significantly determine the final characteristics of the product. Thoughtful design adjustments such as uniform wall thickness and the inclusion of ribs for added strength can enhance the functionality and manufacturability of parts.

Cost considerations are also pivotal in the injection molding process, and understanding the factors that influence costs can lead to more economical production strategies. The price of raw materials, the complexity of the mold design, and the scale of production are primary cost drivers. Economies of scale can be achieved by producing parts in larger volumes, thereby reducing the cost per unit. Minimizing cycle time and using automated systems for part removal and handling can also reduce operational costs.

Quality control is also of utmost importance in injection molding to avoid defects that can compromise the usability and appearance of the final products. Common issues such as warping, sink marks, and incomplete filling of the mold can arise from improper temperature control, inadequate pressure application, or unsuitable material characteristics. Implementing rigorous quality checks and adhering to optimal processing parameters can significantly mitigate these issues. Regular maintenance of molding equipment and molds also plays a crucial role in ensuring consistent quality.

Finally, embarking on an injection molding project requires careful planning and expert advice to navigate the complexities of the process effectively. Starting with a clear understanding of the project’s goals and requirements, and engaging with experienced professionals can provide invaluable insights into material selection, design optimization, and cost management. This preparatory work is essential for aligning the project’s scope with realistic outcomes and setting the stage for a successful manufacturing run.

Why Choose Ponoko

At Ponoko, our cloud-based manufacturing platform has transformed the way businesses approach injection molding by simplifying the entire production process. From design to delivery, our platform provides users with a seamless and efficient experience, eliminating traditional barriers to manufacturing and speeding up the process significantly. With years of experience in plastic injection molding, we have expertise in serving a wide range of industries, including automotive, healthcare, consumer electronics, and more. This breadth of experience enables us to handle projects of all scales, whether it’s a small batch or large-scale production runs, and our understanding of the unique requirements of each industry allows us to tailor our services accordingly.

To ensure the highest quality outcomes, we provide comprehensive support throughout the manufacturing process. Our Design for Manufacturing (DFM) analysis helps identify potential issues in the design phase, reducing the risk of costly modifications later on. We also assist in selecting the most suitable materials for each project, considering factors such as durability, flexibility, and cost-effectiveness. Additionally, our rigorous quality assurance protocols guarantee that every part meets our exacting standards before it leaves our facility.

Our commitment to customer satisfaction is at the heart of everything we do at Ponoko. We collaborate closely with each client to understand their specific needs and objectives, ensuring that we deliver tailored, cost-effective solutions. By reducing production times and costs, we help businesses stay competitive in fast-paced markets, and our goal is to enable clients to bring their products to market more quickly and efficiently without compromising on quality. With Ponoko, clients gain access to a network of experienced professionals and cutting-edge manufacturing facilities, allowing them to focus on growing their business and achieving their strategic goals.

Understanding Plastic Injection Molding

- How long does a plastic injection molding project typically take?

- Plastic injection molding projects can take anywhere from two to six weeks, depending on the complexity of the mold design, the type of plastic material used, and the total quantity of parts required. Simpler projects may take just a few weeks, while those requiring unique materials or detailed specifications can take up to six weeks.

- How do I select the right material for an injection-molded part?

- Selecting the right material is crucial as it affects the part’s functionality, durability, and cost. Common materials include ABS, polyethylene, and polycarbonate, each offering different characteristics. For example, ABS is durable and suitable for heavy use, while polyethylene provides flexibility and moisture resistance. The selection process should consider the intended use, required durability, and exposure to chemicals and extreme temperatures.

- What type of complex designs can Ponoko handle with injection molding?

- Ponoko is known for handling complex part designs with intricate details and advanced injection molding techniques. This capability allows for the creation of parts with complex geometries and fine features that meet exacting standards, particularly in industries such as medical and electronics where precision is critical.

- What is the lifespan of a plastic injection mold?

- The lifespan of a plastic injection mold varies based on the material, design complexity, and maintenance practices. Standard aluminum molds can produce up to 100,000 cycles, while steel molds can exceed 1 million cycles. Regular maintenance, such as cleaning and lubrication, helps maximize the mold’s lifespan within its operational parameters.

- How can I reduce the cost of an injection molding project?

- Reducing costs can be achieved by optimizing part design, selecting cost-effective materials, and producing in bulk. Designing parts with uniform wall thickness improves material flow and reduces waste. Choosing materials that meet performance requirements at a lower cost can significantly reduce material expenses. Producing larger quantities also reduces the cost per unit due to economies of scale.

- What environmental considerations should be taken into account in plastic injection molding?

- Environmental considerations include material choice and waste disposal. Using biodegradable plastics or recycled materials can minimize environmental impact. Additionally, implementing efficient processes that reduce scrap can contribute to environmental sustainability.

- What benefits does Ponoko offer to engineers in the injection molding process?

- Ponoko offers several benefits, including scalability, speed, and precision. Parts can be scaled up or down with no additional tooling charges, and the manufacturing process is not dependent on minimum or maximum order quantities. The precision and repeatability of Ponoko’s injection molding process ensure that parts conform to tight tolerances and meet exacting standards.