A Comprehensive Product Design Guide to Push All Your Buttons

Even with the prevalence of touch-enabled devices in our lives, the tactile button still holds its own as one of the most important physical design elements in a product. Throughout your day, you will encounter dozens (if not hundreds) of examples ranging from the thoroughly satisfying and highly engineered through to the hastily made, poorly molded and barely functional.

Getting those buttons right can be tricky, but thanks to design engineer Christian Brown’s Button Design Showcase we are able to get our heads around some of the important considerations that can help to ensure a successful outcome for your laser cut products.

The laser cutter’s guide to graphic design principles & elements

Everything you need to know about graphic design principles & elements.

“Buttons are a chance for both comfortable ergonomics and increased intuition in your product design… Large buttons surrounded by smaller ones indicate relative importance. A volume rocker button indicates a level going up and down. A single big red button says, ‘PANIC!’.”

How About Button Design for Laser Cutting?

By incorporating Christian’s button design insights with the thinking behind lattice (or living) hinges, we can use these same design principles for laser cutting. Enclosures for DIY electronics projects will often have holes or cavities laser cut to allow for the insertion of mechanical switches or buttons. It would certainly make the design a whole lot more interesting if these mechanical elements can become a more integral part of the laser cut pattern!

Laser Cut Buttons: Integrated

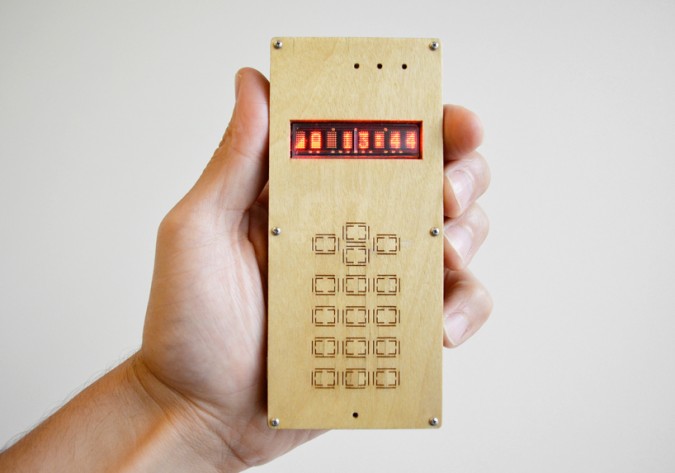

One way to do this is to add integrated spring elements to the surface of an enclosure, enabling buttons to be a part of the product housing itself. The DIY cellphone from David Mellis shows this quite effectively:

Laser Cut Buttons: Materials

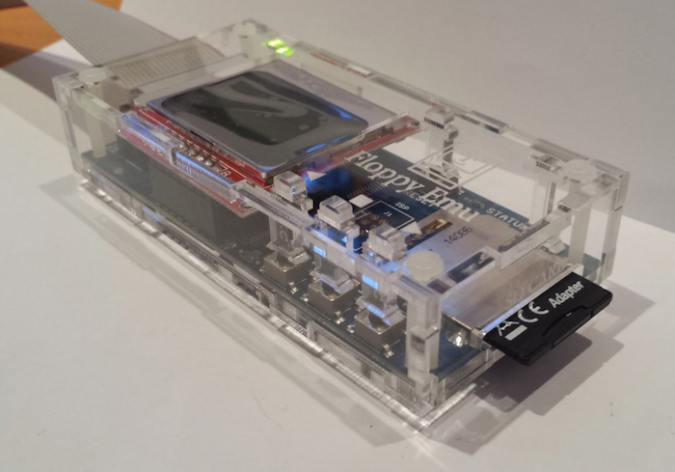

Another option is to use an alternate material that can be fixed to the casing mechanically, much like is done in manufactured products. Alternate materials can include:

- – color contrast (eg: different colored acrylic)

- – translucent (eg: clear acrylic, back-lit for extra zing)

- – rubber/silicone (using laser cutting and/or 3D printing to make a simple mold)

image source: BMOW

image source: BMOW

image source: roland.bz

Learn About Button Design

If your laser cut designs have buttons of any kind, then you should find Christian Brown’s Right On The Button: Using Design as a Showcase for Excellence an interesting read indeed. Gaining an understanding of what goes into the button design for manufactured products can help your own workflow, and aid in using laser cutting to its full potential.

Fictiv via Solidsmack