How Does CNC Programming Work?

The use of CNC machines has revolutionized the manufacturing industry, especially in automotive, aerospace, and electronics, by operating under the control of computers that direct machine tools. The programming of such machines is crucial, as the tool path, which dictates the precise route the cutting tool follows, is complex and must be accurate to produce high-quality parts. However, engineers do not directly program CNC machines due to the immense complexity involved in writing code that dictates every movement of the machine. Instead, engineers utilize CAD software to create design files of the desired part, which are then converted into tool path code via CAM software, automating the process and significantly improving accuracy.

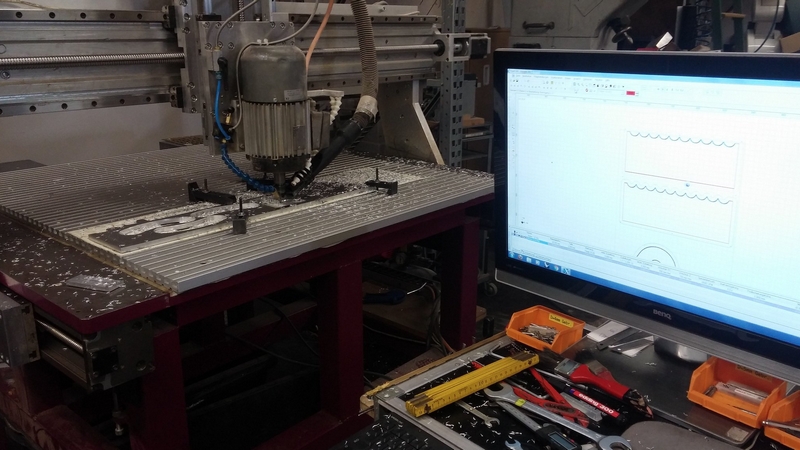

The automation of tool path code generation serves a dual purpose. Firstly, it drastically reduces the amount of manual coding, which would otherwise involve hundreds of thousands of lines of code, thereby saving time. Secondly, it ensures precision and accuracy, as the reliability of automated systems minimizes the potential for human error and enhances the consistency of output parts. Once the tool path code is ready, typically in the form of g-code, it undergoes another conversion process where it is translated into electrical signals, which are then managed by specialized software that convert g-code into electrical pulses. These pulses directly control motors and actuators of the CNC machine, dictating everything from the speed of the spindle to the position of the cutting tool.

The sophisticated conversion process, involving design files, tool path codes, and electrical pulses, enables CNC machines to execute complex manufacturing tasks with precision. The integration of computer technology with mechanical systems allows for the automated production of intricate parts that would be difficult to craft by hand, making CNC machining a cornerstone in modern manufacturing. The seamless flow of data through various software and technologies represents a significant advancement in the field, pushing the boundaries of precision manufacturing and enabling the production of ever more complex components.

CNC Programming Languages

Instead of using standard programming languages, CNC machines operate on G-codes and M codes that direct the machine on the path it should follow during an operation. These codes can include directions on tool movement, speed of operation, and the path to take when producing a part with precision.

G-codes primarily concern themselves with the movement and path of tooling bits, while M codes handle functions that are not related to tool movement. For example, M codes can be used to activate or deactivate drill bits, change tool bits, and even halt the machine and engage warning lights in the event of an error. These functions are essential for both the quality of the machining process and the safety of the operation.

While M codes could be written manually, it is generally avoided due to the complexity involved and the high potential for error. Instead, it is more common for engineers to use software that automatically converts CAD designs into the needed G code.

How to Write CNC Code

While g-code is essential for those operating CNC machinery, it is by no means an easy language to learn. The syntax and functions of g-code need to be understood in great detail, as well as the operations of CNC machinery, because even small errors in g-code can damage materials or cause machine malfunction.

The complexity of g-code also means that it is challenging to provide a brief overview of the language. Numerous commands and parameters need to be considered, and the intricacies of g-code require detailed explanations and practical examples. Websites that provide tutorials on g-code provide step-by-step instructions and video demonstrations that help learners understand the language, and there are many online resources that can help with g-code implementation. By taking advantage of these resources, individuals can learn g-code at their own pace and apply this knowledge to real-world CNC operations.

Overall, g-code is a complex language that is essential for those operating CNC machinery, but it is by no means an easy language to learn. Those who are not involved with CNC machinery will unlikely need to learn g-code, and those who do want to learn it can find numerous online resources to help with the task.

G Code vs. M Code: Differences Explained

As the use of Computer Numerical Control continues to increase, it is essential for engineers to comprehend the significance of G-codes and M-codes in these machines. G-codes play a pivotal role in dictating the movement of the tool head, including rapid positioning, linear cutting, and feed rate control. The difference between G0 and G1 commands lies in their function; G0 represents a rapid positioning command that moves the tool head to a specific location at the machine’s maximum speed, whereas G1 executes a controlled linear movement at a predefined feed rate. This controlled feed rate is crucial for achieving a high-quality finish and maintaining the integrity of the material being machined, making G1 an essential code for most machining processes.

On the other hand, M-codes are used for executing non-movement commands that are critical for the preparatory and concluding stages of the machining process. One common example of an M-code is M104, which signals a 3D printer to heat the extruder to a specified temperature. Another important M-code is M05, which turns off the spindle, a crucial step to ensure safety and prevent damage to the machine or workpiece. This command is typically executed at the end of a machining operation or during a pause in the process.

How to Program a CNC Machine

When it comes to writing g-code for use with CNC machines, having a basic understanding of the programming language is essential. G-code files are text-based, meaning that they can be written and edited using any text editor, and this also means that they are easily shareable and transferable. However, it is important that those who are writing g-code understand that each command placed into a file is read by the machine as a separate instruction, meaning that placing multiple commands on the same line will not work in parallel. As such, it is important to place each command on its own line to ensure that the machine reads each instruction correctly.

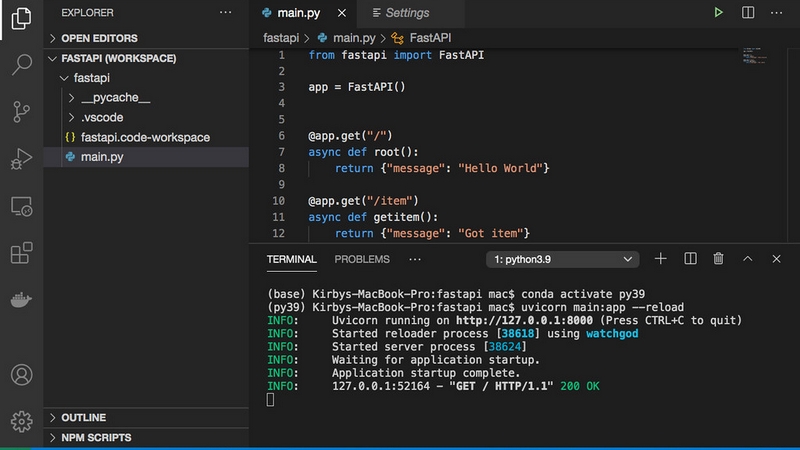

While g-code can be written entirely by hand, there are also software options available that can convert designs into g-code. For those who are working with 2D shapes such as PCBs, free tools such as LineGrinder and FlatCAM can be highly beneficial. For those who need to produce 3D parts, software such as Autodesk Fusion 360 offer a suite of tools that can take a 3D model and produce all the g-code needed to cut and engrave that part.

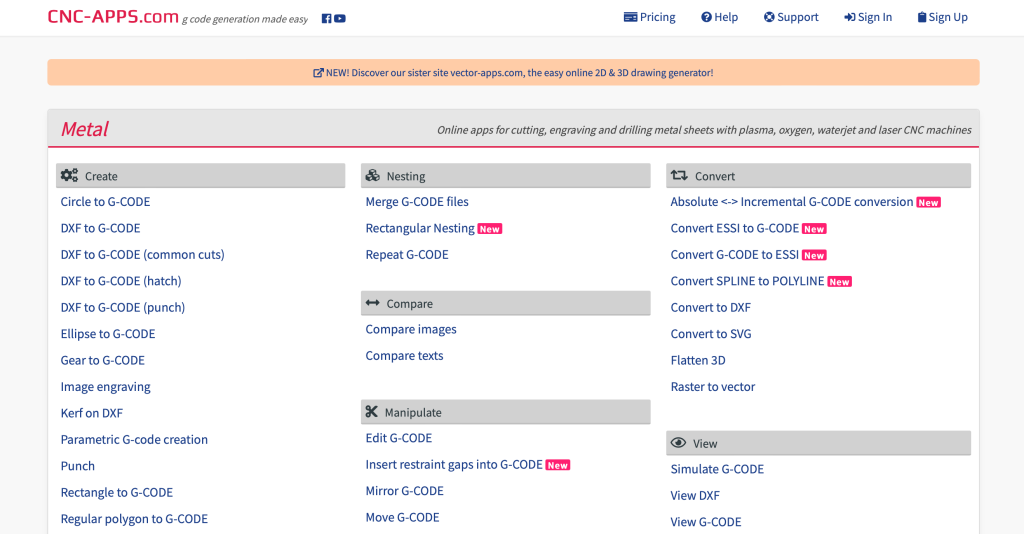

Online tools are also available for those who do not have access to a computer with a text editor, or for those who simply want to quickly generate g-code from a design file. One such tool is available at cnc-apps.com and allows for the conversion of DXF files to g-code, and the ability for this tool to read vector graphics means that the resulting g-code will only cut out the areas of the design file that have no fill.

Key Takeaways

Computer Numerical Control machines represent a cornerstone of modern manufacturing, transforming digital blueprints into physical objects with precision and efficiency. These machines operate under the guidance of commands sent from a computer that are formulated in a specialized programming language called g-code.

G-code itself is comprised of two primary types of commands; motion commands denoted by the letter G, and machine commands represented by the letter M. Motion commands dictate the movement of the CNC machine along various axes, ensuring the cutting tool moves in the correct pattern to shape the material as specified. Machine commands control the operational aspects of the machine such as turning the spindle on or off or setting the appropriate cooling mechanisms in motion.

Writing these codes manually is an exceptionally challenging endeavor. Each line of g-code must be precisely calculated and entered, a process that requires a deep understanding of both the programming language and the mechanics of the CNC machine itself.

Fortunately, for most applications, the manual writing of g-code is not necessary, with a wide variety of software tools being available that can convert digital designs into g-code. Furthermore, CNC operators themselves often handle the conversion of designs into g-code. With their expertise, they can ensure that the machine operates correctly, and that the final product meets the required specifications and quality standards.

Why Choose Ponoko

Ensuring that a CNC part is machined to a high degree of precision and accuracy requires expertise from machine operators, engineers, and technical staff. Professionals involved with CNC machining need to understand the intricacies of the process and the equipment used to achieve the desired outcomes. Precision in CNC machining means that each part produced matches the design specifications, down to minute details that can be as small as a fraction of a millimeter. Accuracy ensures that these specifications are consistently met during production runs, maintaining quality and functionality across batches.

The process of CNC machining starts with the conversion of a design into g-code, which is the programming language read by CNC machines. This step is pivotal as it translates the digital model into precise instructions that the machine can execute, but this step alone does not guarantee a quality part. It is essential to check and recheck that the design and g-code will result in a part that not only looks right but also performs as intended, involving simulations and sometimes creating prototypes to ensure everything works as planned.

For those who find these steps challenging, we offer a streamlined solution by taking the burden off customers’ shoulders. We handle the intricate steps of CNC machining, from g-code conversion to quality checks, and customers can focus on their core activities.

Our extensive experience in rapid prototyping and manufacturing and having produced over 2 million parts for 33,000 customers demonstrates our knowledge and technical know-how. Furthermore, our expertise, built on hundreds of thousands of engineering hours, is embedded in every project, reducing the risk of errors and rework, saving time and money.

By utilizing our CNC machining services, businesses and innovators can free up resources to focus on core activities, accelerating the development of new technologies and solutions, contributing to a better world.