What is CNC Programming?

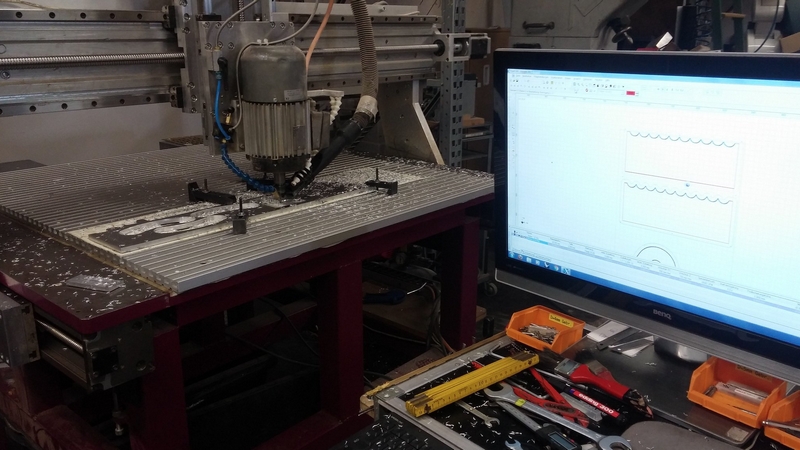

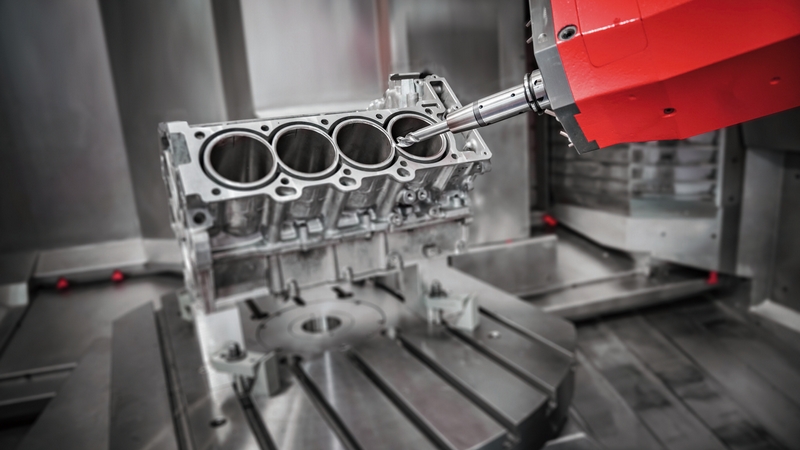

CNC machines, or computer numeric control machines, have represented a significant advancement in the field of manufacturing, particularly for the production of three-dimensional parts. Operating under the control of a computer system, these machines are guided by numeric codes that direct the machine on how to move its tools in three axes (X, Y, and Z) to achieve the desired shape and dimensions of a part. In some cases, CNCs can have more than 4 axis, including rotation in all three axis, as well as the use of multi-jointed arms.

The process of creating a part on a CNC starts with CNC programming, where engineers generate a set of instructions based on a design. These instructions are then handed over to CNC operators who translate these instructions into machine-specific codes, as different machines require different programming.

While it is common for engineers to design parts and then program CNC machines, this is not generally done. This is because engineers focus on designing parts and creating drawings and specifications, which are then given to CNC operators for programming. If engineers were to program machines themselves, small mistakes in the programming stage could lead to major mistakes later on (such as damage to the machine, or wasted material from over / undercutting).

As such the collaboration between engineers and CNC operators is essential in the production of high-precision parts. Engineers provide the expertise in design and specifications, while CNC operators provide their expertise in CNC operation and programming. Through this synergy, the capabilities of CNC machines can be fully leveraged, leading to increased efficiency in production processes and expanded possibilities for product design and innovation.

How Does CNC Programming Work?

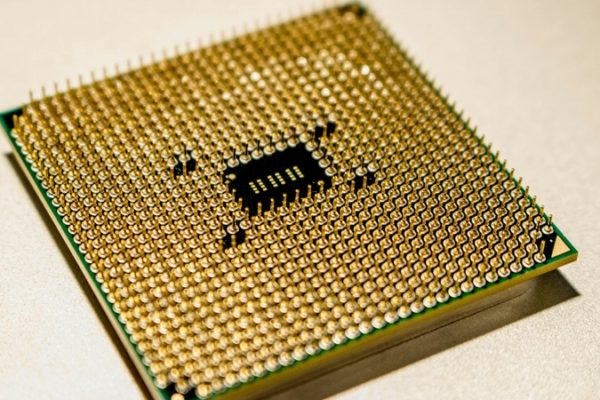

As the instructions sent to a CNC machine are in the form of binary data, trying to program a CNC using native codes is effectively impossible. To start, the machine itself consists of various motors and actuators that all need to be controlled with the use of electronic pulses. These pulses are essential as they determine the movement of motors, engagement of power systems, and the rotation of bits needed for machining tasks.

The generation of these signals is managed by a controller that is connected to a computer and receives its instructions from there. The computer sends commands to the controller which are then translated into electronic pulses, and the precision of these pulses directly affects the accuracy and performance of the CNC machine. When programming a CNC, numerous factors including speed, feed rate, and axis manipulation all need to be taken into account and synchronized.

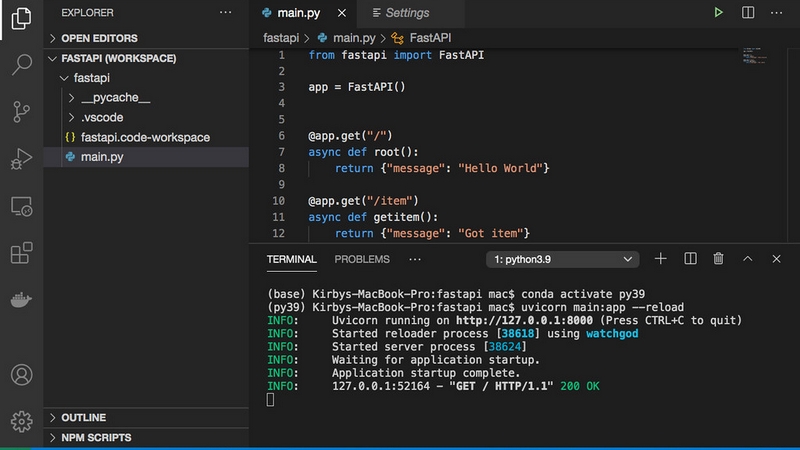

To help with this, special software is used that manages control signals and ensures that the correct sequence and magnitude of pulses are delivered. This software also helps by deriving control signals from g-code which itself is a specialized programming language for CNC machines. G-code provides instructions on executing various machining operations such as lines, arcs, and drills, but again, it is not written by hand. Instead, it is generated from 3D models that are converted into a series of flat patterns that the machine can follow.

What Are the Codes Used for CNC Programming?

The instructions that dictate the movements of a CNC are encoded in a language called g-code, the standard language used in CNC programming. G-code commands are sent to the machine’s controller, which then translates them into electrical pulses controlling motor actions. G-code is versatile, containing commands that instruct the machine where to move, how fast to move, and what path to follow.

Despite standardization of many g-code commands, the diversity in controller designs from different manufacturers means that certain g-code commands may not be universally compatible across all platforms. However, there are at least 100 g-code commands that are widely recognized by most machines, prefixed with the letter ‘G’ and a numerical code specifying the action to be taken. For example, G00 is used for rapid movement without regard for the path of the tool, while G01 is used for controlled movement at a defined feed rate, crucial for tasks where the path of the tool needs to be precisely controlled.

G-code commands can be enhanced with additional parameters such as speed, feed rate, and distance, allowing for more complex and customized programming. For instance, G01 can be modified with feed rate and distance parameters to specify a rapid movement of a tool to a specific position. The use of g-code and its variations enables efficient and precise operation in a wide range of machining processes, from milling and drilling to cutting and engraving.

The ability to customize g-code also enables for adaptive and intelligent machine operation. For example, g-code can be combined with sensor data and real-time monitoring to adjust machine operation in real-time. Such feedback loops can be used to optimize machine performance, improve quality, and reduce waste, enhancing the efficiency of manufacturing processes.

As g-code is widely used and standardized, it makes machine programming and machine matching straightforward. This simplicity of operation also makes g-code machines easily maintainable and repairable, as the vast majority of machine controllers and g-code books are widely available. The widespread use of g-code also means that there are numerous resources available to machine operators, including online forums and programming guides.

However, the reliance on g-code also means that machines can become outdated as new g-code commands are introduced, or machines become dependent on specific brands and designs. This can lead to increased costs in reprogramming and refurbishing machines, hindering the efficiency of manufacturing processes. The need to balance the use of g-code with technological advancements is essential to ensure the long-term performance of automated machinery.

How to Write CNC Code

When it comes to CNC machines, their programming is a crucial step in the manufacturing process. However, writing g-code from scratch is a challenging task that is not recommended for several reasons.

Firstly, the complexity and precision needed to write error-free g-code make it difficult to produce accurate results. Even a small mistake can lead to incorrect machining, which in turn can damage the machine, waste material, or pose a safety risk. Instead, it is generally advised to use software tools that can automatically convert a design into g-code, eliminating the potential for human error. These tools also have the added advantage of being able to adapt the generated g-code to specific machine tools, ensuring compatibility and optimal performance.

However, for those who want to manually write g-code, there are resources available. YouTube is an excellent platform for learning about CNC programming, with many tutorials and guides available that can help users master the art of writing g-code. Many experienced machinists and programmers have shared their knowledge and insights, making it a valuable resource for those looking to deepen their understanding of CNC programming and its nuances.

Overall, while writing g-code manually may be possible, it is not a practical task for those who do not have personal CNC machines. Instead, it is recommended to use software tools that can automatically convert designs into g-code, ensuring accuracy, precision, and compatibility. However, for those who want to learn about CNC programming and its nuances, YouTube is an excellent resource that provides step-by-step guides and insights from experienced programmers.

CNC Programming Software Options

The utilization of CNC services simplifies the manufacturing process for many businesses and hobbyists alike as CNC services eliminate the need for specialized software. Companies offering CNC services handle all aspects of the production process, from design submission to the final machining, making it a hassle-free solution for producing precise and high-quality parts.

Those who prefer to operate their own CNC machines can take advantage of the numerous software options available, with Mach3 being a notable example due to its reliability and compatibility with older CNC machinery. Mach4 represents an evolution in CNC control software, offering modern hardware compatibility while retaining the core functionalities of Mach3.

LinuxCNC presents an open-source alternative, supporting a wide range of machines and machines without the need for proprietary licenses. LinuxCNC runs on Linux, making it an attractive option for those on a budget, and the open-source nature of the software allows for customization and flexibility.

The ability for LinuxCNC to run on a Linux system also makes it accessible to those using Linux operating systems in educational and startup environments. The wide spectrum of options available whether choosing a service-based approach or investing in personal CNC equipment ensures that CNC machining is accessible to all.