Filament making machine winds its way toward finishing its Kickstarter campaign rewards

We last looked at Filabot, the plastic extrusion filament maker for Makerbot and RepRap style 3D printers when Tyler McNaney was in the middle of his Kickstarter Campaign, that ended up successfully raising $32,330 and was more than 320% funded.

We last looked at Filabot, the plastic extrusion filament maker for Makerbot and RepRap style 3D printers when Tyler McNaney was in the middle of his Kickstarter Campaign, that ended up successfully raising $32,330 and was more than 320% funded.

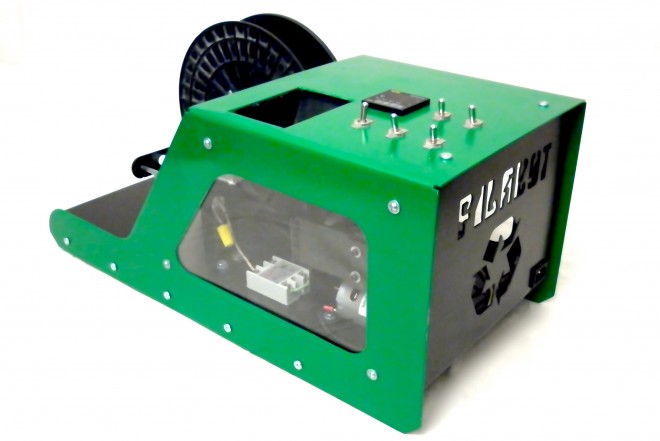

The Filabot is a desktop machine that aims to help reduce the cost of 3D printing for filament based and reduce plastic waste by turning it into “ink” or filament for 3D printers that print by depositing and fusing plastic together.

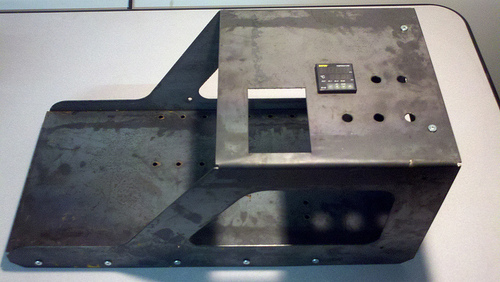

The Filabot Reclaimer has recently had a lot of development work from McNaney, whose working hard to fulfil his Kickstarter rewards orders by the end of the year. He, recently revealed the design for the production Filabot Reclaimer on his website. The case is made from folded CNC plasma cut steel.

As well as desktop Fused Deposition Modeling (FDM) 3D printers’ favourite plastics ABS and PLA, McNaney says his machines should also be able to process common household plastics such as nylon 101, HDPE, PET and LDPE into 3mm or 1.75mm diameter filaments.

Once the Kickstarter orders are finalised McNaney hopes to open orders up to the public and produce the machines on a larger scale. “By the end of this year, we are optimistic about having all of our 67 kickstarter systems completed and on their way. Once we are done with our kickstarter backers, we will then proceed with launching to the public. When we ship Filabots, there will be a little surprise…..and of course it involves recycling.”

As desktop 3D printing can be a little hit and miss, at least when you’re starting out, Filabot Reclaimers are probably the biggest innovation to happen in the area of desktop 3D printing for sometime. They should be a significant step towards moving 3D printing towards a viable closed loop recycling system where failed prints and plastic waste that you would otherwise dispose of in landfills, can be reused and up-cycled into useful filament to be used for printing new creations.

https://www.youtube.com/watch?feature=player_embedded&v=DMNLJUKKNhQ

David is an industrial designer from New Zealand. He contributes a weekly article on personal fabrication for Ponoko. Follow him on Twitter!