The Electric Eel Wheel Successfully Spins Its Way Into The $43+ Billion Crafting Industry

If you think knitting and crocheting are only for grandmas or that macramé and woven wall hangings were just a fad in the 1970s, think again. Thanks in part to festival fashion, yarn arts are alive and well…and growing.

In fact, 38 million people knit or crochet according to the Craft Yarn Council—including celebs such as Cameron Diaz, Daryl Hannah, Julianna Margulies, Sarah Jessica Parker, Julia Roberts, Hilary Swank and Vanna White. And the Association For Creative Industries says that the U.S. creative products industries are valued at $43 billion.

There are more craft-related blogs, websites and tutorials than ever before. YouTube has 12,000 woven hall hanging videos, 400,000 macrame how-tos, 2.6 million knitting tutorials and 3.6 million crochet trainings. You could spend days on Instagram getting inspired by #bohemianstyle, #yarnlove and #makersgonnamake. Pinterest is filled with DIY yarn craft ideas. Craftsy offers lessons in 18 types of creative arts.

While these kinds of artistic expression provide a creative outlet, reduce stress, improve mood and build confidence, many makers are finding there is a business opportunity as well. On Etsy, there are 13,000 listings for woven wall hangings, 228,000+ macramé items, nearly 700,000 knitted products and 1.18 million crocheted designs.

That’s a lot of yarn.

Most of this yarn is purchased off the shelf. But for those master crafters, making your own yarn adds another layer of depth and control to the creative process. And the Electric Eel Wheel can make that spinning process a whole lot easier—and affordable.

Reinventing The (Spinning) Wheel

Maurice Ribble, founder of Dreaming Robots, is an engineer that likes to take the output of scientists to the next level and solve multidisciplinary problems—issues where he can work on electronics, software, mechanical design, and human interfaces and factors. His wife Emily is an avid knitter and yarn spinner. And she had a problem: Her spinning wheel sucked.

Like any good husband with a can-do attitude, Maurice set out to solve the problem. “I knew I could design something just as good or better than my wife’s garage sale treadle jalopy,” he says.

She had a foot powered or treadle spinning wheel, the most common type of wheel today. (Sleeping Beauty or Rumpelstiltskin anyone?) These spinning wheels generally range from $400 to $1,000.

With advances in technology and production, Maurice understood it was possible to construct an electric spinning wheel for less than traditional treadle wheels. But many electric spinning wheels are surprisingly expensive.

“You might expect electric spinning wheels to be affordable because of the low cost of electronics and motors these days. But that’s not the case,” he says. “It’s typically $800 to $1,600 for quality electric wheels.”

While some auction sites have electric spinning wheels for around $250, Maurice says his experience is that these are low quality and are not recommended by most of the people who have used them. “These are often poorly designed using a hodge-podge of materials like sewing machine motors and plastic tubing to hold things together,” he says. “This gap in the market was part of the inspiration for the Electric Eel Wheel.”

Introducing The Electric Eel Wheel

Because of this lack of affordable electric spinning wheels, Maurice got to work on designing an electric spinning wheel that would meet the stringent criteria of master knitters while keeping the cost affordable and accessible for all skill levels. And the Electric Eel Wheel (EEW) was born.

“With the Electric Eel Wheel, I was trying to bring the price down from more than $1,000 to around $250,” Maurice says. “While there are some electric spinning wheels in the $250 range, they are of low quality and don’t spin very well. I wanted to find some sweet spot where I could make a quality spinning wheel at an affordable price.”

The main function of a spinning wheel is to both twist fibers and put them onto a bobbin. There are literally hundreds of sources for fiber. This can be anything from certain plant fibers such as flax and bamboo, or animal fibers such as sheep wool, llama and alpaca hair, cashmere goat wool, silk, or even cat and dog hair. (We’re kinda partial to goats.)

The fiber is processed and washed before it is carded (or combed) to align it to make the spinning process easier. At almost any stage, fiber can be dyed. At this point, the fibers are called roving, which can then be spun into yarn.

This is where the Electric Eel Wheel fits into the process. A carded strand of fiber is pulled from the roving and fed into the wheel. The yarn is made by putting a twist into the roving to give it strength. Spinning two or more of those strands together makes a thicker, multi-ply yarn. Check out how it works:

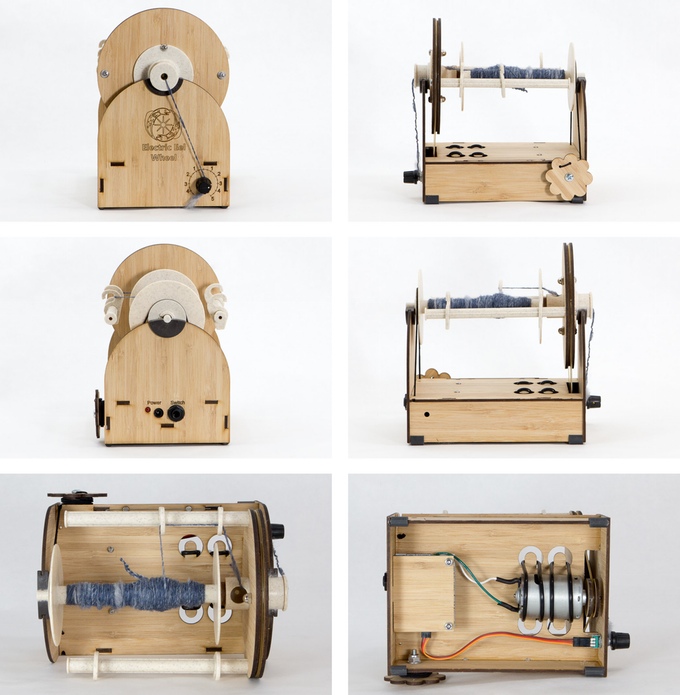

What makes the Electric Eel Wheel different from other electric spinning wheels? The uptake is controlled with a unique scotch tension design, and the yarn flows through a clever flyer assembly. It has three different orifice hole size options to accommodate thin lace weight to super bulky yarn. You can even create artisan yarns using beads or conductive threads. And since there is no treadle, it can be used in more places—such as your recliner!

The Electric Eel Wheel is also small and lightweight, making it great for people with physical limitations. Its size also makes it very portable spinning. You can even take it with you on long road trips, as it will run off a battery pack or the 12V power jack in the car. (Passengers only please! Drivers keep you hands on the wheel and eyes on the road!)

Working With Ponoko

When Maurice first began designing the Electric Eel Wheel, he considered a more traditional wooden case from furniture makers. “I even built a prototype in my basement, but it would have been a lot more work to iterate and try other ideas,” he says. “Also, this would have been a heavier solution and thus cost more to ship.”

He also thought about manufacturing with CNC machines. “But with CNC, you can’t get square internal corners, and that was pretty important for how I wanted to assemble my product,” he explains.

Thus, Maurice says that laser cutting was an obvious manufacturing choice for a number of reasons, with one of the most important being how fast he can iterate.

“One of the often overlooked advantages is how easy it is to iterate and try new designs with laser cutting,” he says. “Being able to get a new prototype in a week is a game changer and has helped my products immeasurably. I did well more than 10 different prototypes with Ponoko. I could try out all my ideas, and the final product is a combination of the best ones.”

For Maurice, “final product” isn’t always quite final. After releasing the Electric Eel Wheel, he saw a number of areas for improvements. So he continued to finesse the details and introduced the Electric Eel Wheel 2 (EEW2). Then EEW3…and EEW4 in 2015. Now he’s back at it again with the release of EEW5.

For this latest iteration, Maurice chose the 2.7mm Amber Bamboo to laser cut case that holds the motor, electronics and some plastic parts the control the flow of yarn.

“It’s strong, beautiful, economical and light weight,” he says. “This is an important consideration because it cuts down on the shipping costs. The first version of my spinning wheel weighed several pounds more than the current version, and this added up to a lot of shipping costs (especially for international shipping).”

In addition to choosing the right material, Maurice used another tactic to lower making costs: Nesting. (Learn how to save material—and money—with The Definitive Guide To Nesting Software For Laser Cut Designs.) “When I started nesting my designs to share cut lines, my costs for laser cutting the cases dropped by more than 25%,” he says.

Another cost-savings tip Maurice would give any laser cutting newcomer is to make sure to delete any lines outside the cutting region because they count towards your laser time—and the overall cost of the design.

“The way I design things using Adobe Illustrator is to put all the basic geometric shapes in the right places. Then I use the union and intersection tools to create the final shapes,” he explains. “I keep all the original geometry outside the cutting area so I can easily adjust parameters in the future. However, you must to delete those shapes in the version sent to Ponoko. Normally I do this when converting from an .ai file to an .eps file. Otherwise, the pricing algorithm charges you for those cut lines.”

Crowdfunding With Kickstarter And Exceeding Goals—Twice

That first Electric Eel Wheel turned out quite well and a lot of Emily’s spinning friends were asking if he could make them a modern portable spinning wheel, too. He did, and as he continued he would find aspects that could be improved. Each generation of the Eel Wheel has had improvements on the previous generation.

The demand grew, and by the fourth iteration Maurice expanded the Electric Eel Wheel offering by launching a Kickstarter campaign in 2015. He set a modest goal of $5,000—which was reached in three HOURS! During the one-month funding period, the EEW4 had 245 backers who pledged $53,931 to bring the project to life.

In 2016, Maurice returned to Kickstarter to launch the Electric Eel Wheel 5, which had even more improvements and enhancements over the previous models. He again began with a $5,000 goal. This time, funding was achieved in 1.5 HOURS! In the first two days of the campaign, he was at 600% over goal, completely exceeding expectations.

For the EEW5 campaign, Maurice added four levels of stretch goals at $25K, $50K, $60K and $75K. Each one was met during the 28-day funding period. In total, he received $92,201 in pledges from 428 backers to completely roll over all his funding goals.

How did he raise funds so quickly and exceed every financial goal set? A GREAT email list. “A big reason we have so much funding so quickly is I maintain an email list of people who have are interested in these products. I’ve built up this email list throughout years of giving out free information and resources to spinners,” he explains.

While Maurice says it has been amazing how much interest people have had in the Electric Eel Wheel throughout both Kickstarter campaigns, the most important thing backers have given is feedback on how to make the product better. He received many ideas on things that could be improved and was able to implement the ones that resulted in a better product while still keeping it at an inexpensive price point.

“It’s a delicate balance of implementing the good ideas without having big delays or increasing the cost of our product,” he says. “While we certainly didn’t implement all the new ideas people gave us during the Kickstarter, we were able to implement several—such as making a custom plastic card that helps measure yarn gauge.”

Another new twist for the EEW5 campaign was to offer something unexpected with premium backing options. For those spinners who not only want a functional electric wheel but also one that is beautiful, Maurice created a level that included hand-painted Electric Eel Wheels. There were four design options—butterfly, Celtic (shown), dogwood and thistle—and backers could choose the colors.

Spinning Into The Future

What’s next for Maurice and the Electric Eel Wheel? The Kickstarter campaign for EEW5 just finished with all product shipped before the target date of May 2017 (a rarity, he says, in the Kickstarter world).

For those interested but who missed out on the Kickstarter promo, he will be selling the EEW5 in his online store dreamingrobots.com/collections/electric-eel-wheel. (Just sign up for an email to be notified when the EE5 is in stock and available for purchase.)

Maurice is a believer in open sourcing his designs so other makers can either use them to make their own small electric spinning wheel or add to/improve upon the designs to meet their own needs. He just released the source code for EEW5 on GitHub and the code for Electric Eel Wheel versions 1-4 is available here.

While there are no plans in the works for an EEW6 yet, that doesn’t mean Maurice is sipping Mai Tai’s and basking in Kickstarter glory. No way. He’s still working out tiny details on the EEW5 for constant improvement.

“Right now there are hundreds of people testing the EEW5, and little issues are showing up,” he says. “We’re making small adjustments to make it better. We are also researching possible accessories for the EEW5. So for awhile, I’ll be focusing on make the EEW5 better.”

To stay up-to-date with the Electric Eel Wheel, visit dreamingrobots.com, follow updates on Facebook and watch video tutorials on YouTube.

In the meantime, we’re going to be practicing our knit and purl stitches!