Laser cutting is cheap, but that doesn’t mean you should rush your first project. By taking time and avoiding these three common mistakes, you will get professional results first time, eliminating the need for successive prototypes (unless of course you decided to change something about your design).

Introduction

There is no doubt that laser cutting is a cost-effective solution. However, just because laser cut parts can be turned around so quickly doesn’t mean you should waste money on prototypes that either didn’t need to be manufactured, or could have been designed better. To minimise the chances of errors cropping up in your designs, here are the top 3 biggest mistakes to avoid when getting your next metal laser cut parts!

Mistakes To Avoid

Plenty of online resources exist when it comes to avoiding mistakes, but these are generally geared towards those who own and operate laser cutting machines (for example, making sure the power levels are right, or that the laser has been correctly aligned). Thankfully, our in-house engineering experts already know the ins and outs of laser cutting, meaning that these problems will never be a concern for you.

For example, our curated range of engineering materials are all laser-safe, each material is matched to a specific cutting station, and all laser stations are routinely calibrated. Thus, anything that goes wrong with a part is rarely due to the machine setup, but due to the design itself.

Problem Number 1 – Considering Deviation In Part Measurements

When designing parts to be cut, it is easy to fall into the trap of designing parts as if they were being CNC machined. However, laser cutters are not CNC machines, and as such, parts being cut by laser cutters have tolerances that need to be taken into consideration.

The first challenge faced by engineers is that laser beams diverge as they leave the laser head, and this divergence directly affects the width of the cut. This means that parts being cut have a wider cut width on the underside compared to the top side, and this can be problematic for parts that require both sides to have the same dimensions.

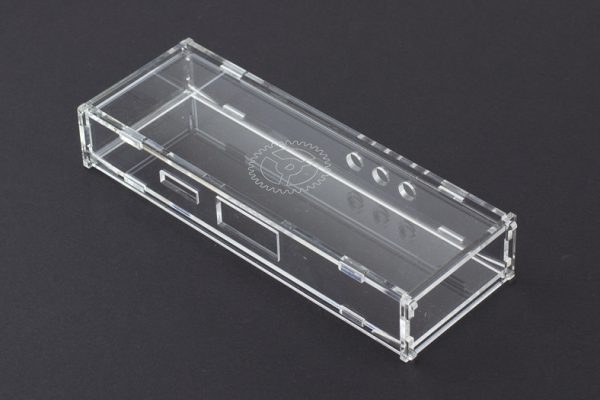

For example, a faceplate for an enclosure may have a slightly tapered edge, and this can result in a slight gap around the edge of the faceplate when installed. Furthermore, the divergence of the laser beam also results in a wider cut width on the underside of the part, and this can make it difficult to mount parts together. As such, engineers need to take into consideration the divergence of laser beams when designing parts that interconnect.

This variation in beam width also means that designs with interlocking parts need to consider the extremes of these tolerances. For example, two parts that would normally fit well together could have tolerances at the extremes, one being slightly larger and the other slightly smaller, meaning that they will no longer be able to mate.

Problem Number 2 – Warping

Warping is another challenge that engineers can face when using laser cutters to fabricate sheet metal parts. The use of a laser beam to cut metal causes the metal to heat up, and this heat can cause the metal to expand.

However, as this expansion of the metal may not always be uniform, the metal can potentially warp (the manufacturing method of the material can also affect warping). This warping can be problematic for engineers as parts that are designed to fit together may not fit.

Furthermore, warping can also be problematic for structural parts, as warping can reduce the strength of the part. As such, engineers need to be careful when using laser cutters to fabricate sheet metal parts, and may need to consider using thicker sheets of metal or reducing the complexity of their design.

Problem Number 3 – Laser Kerf

Laser kerf is a phenomenon that occurs when laser beams diverge as they cut through material. This divergence results in a wider cut width on the underside of a part compared to the top side, and this can be problematic for parts that require both sides to be identical. However, as laser kerf is related to the thickness of a part, it is generally only an issue for parts that are thick.

An example of how laser kerf can affect a design can be seen in faceplates. If a faceplate for an enclosure is made from a thick material (typically greater than 3mm), the underside of the faceplate will have a narrower edge. When placed up against a flush surface, the underside of the faceplate will have a tapered edge, showing a gap between the two surfaces.

While laser kerf cannot be avoided, its effects can be minimised by keeping the kerf side internal to a deign. For example, when laser cutting a faceplate, it is important to make the underside of that face inside the enclosure, with the topside being the visible side.

Tips for Laser Cutting

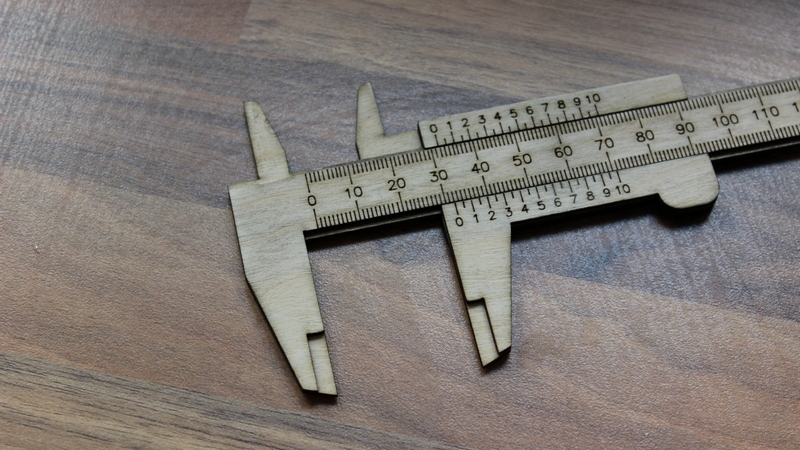

- Measure Twice, Cut Once

- Always double check all measurements for your part, and be absolutely sure that it will fit as needed.

- Use the right material!

- That gold acrylic plastic may look beautiful in your design, but it is mechanically appropriate? Always double check the material parameters during selection, and make sure that the chosen material is suitable for your design

- Watch the thickness of your part

- Laser cutters are subjected to an effect called laser kerf whereby the width of the cut gets bigger the deeper a laser cuts into a material. As such, thicker parts will have a greater degree of kerf, which needs to be considered in the final part.

- BYOM – Bring Your Own Material

- In some extreme cases, you may require a really specific material (such as an aerospace-grade fire-resistant plastic). If this is the case, just let us know and we will see how we can incorporate this material into our laser cutting process

Any good engineer knows that it is imperative to measure twice and cut once, and the same applies to online laser cutting services such as ours. The more times that you check a design before sending it off, the lower the chance that something will go wrong (of course, if you spend too much time worrying about it, you may end up introducing mistakes, so, like life, it’s all about balance).

Arguably the first and most important consideration to make is the material being cut. Simply put, metal is not all the same, and different metals can behave very differently when being cut. For example, some metals may be more prone to warping, while others are more suspectable to forming burrs and sharp edges.

The thickness of the material also needs to be taken into consideration as this can affect the quality of the final part. Thicker materials can help to produce higher quality parts (due to the resistance against thermal differentials), but this comes at the cost of a larger laser kerf. Thinner materials are generally easier to cut, but this can make them more prone to breaking.

Finally, in some edge cases, it can be beneficial to source one’s own material for laser cutting services. While Ponoko offers a wide range of engineered materials, it is possible that a customer may require a material that is not stocked by Ponoko. In these cases, Ponoko is able to accept custom material, and this can be especially useful for applications that require a high degree of precision and accuracy.