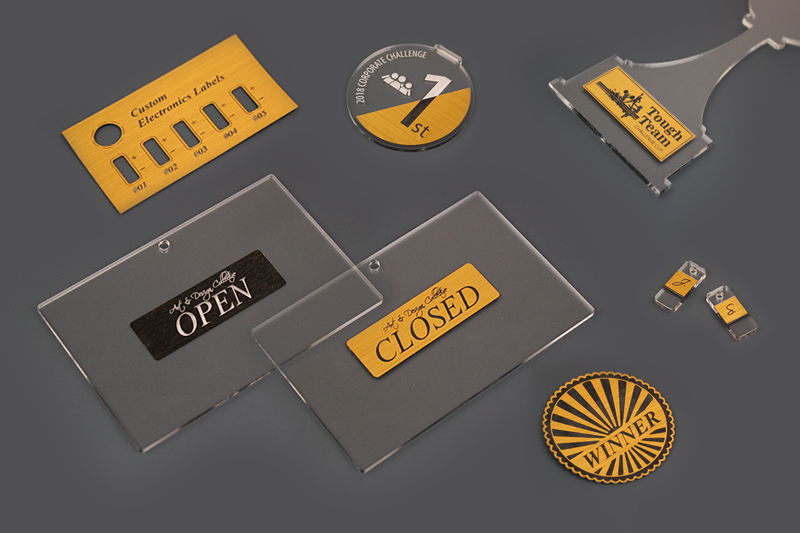

Custom Laser Cut Acrylic Logo Sign

Laser engraving is an excellent manufacturing method for 2D parts, and with the wide range of materials that Ponoko has in stock, custom laser cut acrylic signs are an excellent project, whether it’s for a commercial product, or just as a starter project when working with online laser cutting services. Acrylic signs are perfect for many different locations, including inside offices, at desks, and even outside thanks to their weather resistant nature.

Because acrylic is easy to work with, they can be cut into any shape involving all manner of complex details, and as engraved acrylic shows extremely well, they are perfect for catching the attention of those who walk by them. If used in combination with a side light (i.e. a bright LED light source that shines in through the side), then any engraved area will glow brightly, especially when using clear acrylic. This can give the impression of a hovering graphic, which is not only striking, but also highly professional and futuristic.

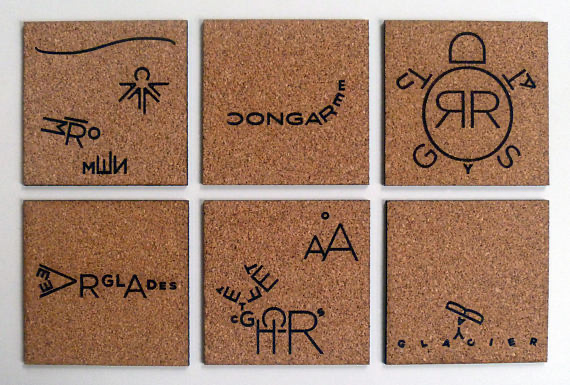

Custom Cup Coasters

When creating office environments, it is always important to think about the impression that it gives to guests who could be potential future employees or investors. As such, having nice furniture with matching branded cups can really help to bring the aesthetic level of the office space to that next level.

However, someone coming in with a hot cup of coffee (or tea, if you are British), could very easily stain and mark that impressive office furniture, meaning that cup coasters will definitely be a must. As such, instead of opting for an off- the-shelf solution, custom laser cut cup coasters can be manufactured that not only help to create a solution that blends in perfectly to your environment, but also integrates the brand, whether it’s the logo, slogan, or even the name of individual employees.

But these coasters don’t just have to remain in the office; they could very easily be used as swag in gift options and handouts at major events, further establishing your brand. These cup coasters can be made from numerous materials, including aluminium, stainless steel, acrylic, and wood, and thanks to the wide range of finishing options provided by Ponoko’s software manufacturing service, you will always be able to get the exact look you need.

Custom Engraved Business Cards

Everyone these days seems to have a business card, containing forgettable information such as your name, email, and telephone number. Considering that so many business cards end up in the bin, it almost makes you wonder if there is any point in getting them in the first place.

Well, instead of going with the standard card options, you can get business cards made using online laser cutting services. Unlike your typical business card, these cards would be limited to only extremely special individuals, being made from metal, plastic, or wood (with the material reflecting your brand). For example, a business card made from wood could be used to show environmental concern, while those made from metal could give a sense of engineering knowhow. Regardless of what the card is made from, these cards would be something that no individual could ever throw out, and the ability for all our materials to be engraved means that any business card made using our service would put all others to shame (including those ordered by Patrick Bateman).

Basics of Laser Engraving

Laser engraving is a process that is very similar to laser cutting, but instead of cutting all the way through the material, it only removes the outermost layer. This is achieved by either moving the laser beam at a much faster speed across the material, reducing the power of the laser beam, or a combination of both.

Furthermore, laser engraving is also able to be done in the same machine cycle as the cutting, meaning that the part doesn’t need to be prepped or moved. Not only does this help to significantly decrease manufacturing times, but also reduces the overall cost.

However, because laser engraving can burn the surface of a material, it can result in a burnt appearance. This is mostly true for wood (due to the carbon content), and while this burnt appearance can be desirable for some designs, it may not be for others. For non-carbon containing materials (such as metal and plastic), engraved areas can either be left as is, or filled with an ink to increase their overall contrast.

Proper Materials for Laser Engraving Projects

When it comes to laser engraving, the choice of material is crucial as not all materials can be engraved.

Of all material options, wood is ideal for engraving thanks to its ability to burn when exposed to intense heat. The burning of wood results in a deep contrast between the engraved design and the surrounding material, and this makes wood ideal for graphics, art, and text. Furthermore, wood can be engraved with both vector and raster designs, and the burning of wood also makes engraved designs more resilient to wear and tear.

Paper is another material that can be engraved, but due to its extremely thin size, it is rarely recommended. If a paper-like material is required, then cardstock will give the most reliable results, but even then, it is often preferred to use a printing method such as screen printing or inkjet.

Clear acrylic engraves incredibly well, and is extremely common in signage and other graphic applications. One major advantage of acrylic is that if light is shone through the side, only the engraved areas will be lit up. This creates a hovering effect, whereby a piece of artwork can appear to be suspended in mid-air. In contrast, dark acrylics do not engrave well simply due to the lack of major contrast, and therefore is generally not recommended.

Metals are an excellent candidate for engraving due to the ability for the engraved design to be heavily scratch resistant. While engraved metal may not have a strong contrast ratio, it takes a lot of sanding and polishing to remove an engraving, making it excellent for engineering applications such as serial numbers, faceplates with critical information, and safety systems.

Tips for Designing Your Laser Engraving Project

Always Use Vectors!

When designing a laser engraving project, it is essential that the design is done so in a vector format. Vector designs are ideal for describing the outline of a shape, and these can easily be scaled up and down without losing any quality. Furthermore, vector designs are also ideal for describing complex shapes such as logos. Even though raster designs are ideal for engraving complex images, they can quickly become pixelated and blurry if the resolution is too low. As such, it is essential that raster designs are done at the highest resolution possible.

Choose the Right Material

When choosing a material for engraving, it is essential that the material chosen has a good contrast between the material and the engraving. Light-coloured materials such as wood, paper, cardboard, and plastics are ideal for engraving as they provide a clear contrast. Metal can also be engraved, but only if the metal is light in colour. Dark-coloured materials are generally not ideal for engraving as the engraving can be difficult to see.

Overall, choosing the right material and file type is essential for producing high-quality engravings.