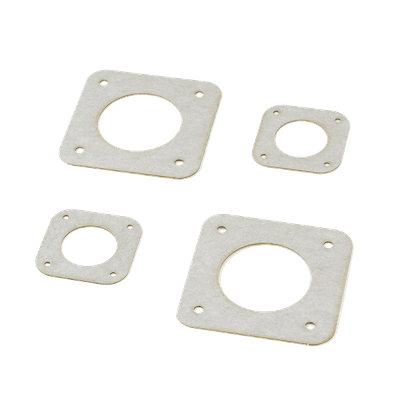

Grey Vulcanized Fiber

With a high strength to weight ratio, vulcanized fiber is an excellent choice for designs that need good mechanical properties. This material is made of cotton fabric that’s been treated to make it hard and dense.

Same day turnaround

Design specifications

Maximum sheet size

23.5 x 11.5in

Kerf width

0.01in

Minimum thickness

0.09in

Maximum thickness

0.09in

Minimum overall part

0.24in

Minimum feature size

0.04in

Minimum engraving detail

0.04in