Laser cutting service for San Jose, online ordering — parts delivered same day or money back.*

Parts cut to 0.13mm accuracy with 99.3% quality record.

"Using Ponoko gave me the ability to create what I wanted with least amount of investment of time and money."

"We see this as the beginning of something huge"

Cloud manufacturing technologies to accelerate your hardware build.

Startups & enterprises rely on our cloud accelerated prototyping & production, to build the next great products.

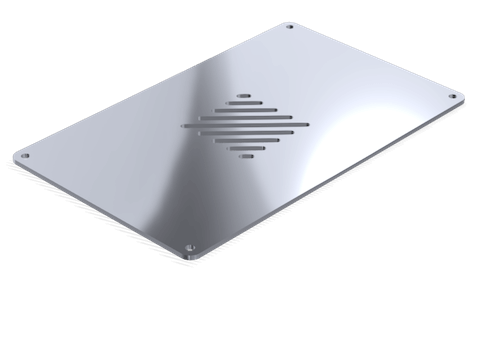

Sheet Metal Fabrication

- ±0.13mm Dimensional accuracy

- 3000x1500x25mm Max part size

- 15x15x0.4mm Min part size

- 1x1mm Min feature size

- ISO-9001, ITAR

- Same day Min lead time

Laser Cutting & Engraving

Sheet Metal Photochemical Machining

3D Printing

Injection Molding

Assembled Printed Circuit Boards

Aluminum Faceplate

Software powered laser & engraving service with over 200+ engineering-grade materials, no minimum order size, and free instant quote for any design for customers in San Jose

Have your components quoted and laser cut on the same day at our facility in San Jose. Our automated system can instantly quote your urgent part immediately then ship it out the same day. Spend less time waiting for parts, and more time developing your product. Get your parts fast to accelerate time to market, meet schedules on time and impress your customers. Ponoko's high precision laser cutting is quality guaranteed at every stage of production. Better than 99.3% of laser cut components meet our customers' strict quality standards. Your satisfaction is guaranteed or we will remake your parts and ship them free of charge. Ponoko provides an instant quote, so you don't have to wait for someone to contact you. Order with confidence - our account terms promise to protect the confidentiality of your IP, including a non-disclosure agreement. With no minimum order quantity we can easily supply you with customised laser cut parts for any production volume.200+ laser cutting materials online.

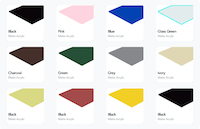

Material selection for laser cutting can be challenging, and this problem is made worse when trying to get a chosen material sent to a manufacturer in San Jose. To keep material selection simple, we have a specially curated list of over 200+ engineering-grade materials that are not only designed for use with laser cutting but have carefully documented and controlled properties such as tensile strength, electrical conductivity, and density. This level of consistency ensures that each part manufactured is identical as well as provides predictable behaviour.

How we deliver custom cut parts in San Jose, same day from $50 for just 1.

When it comes to ordering laser-cut parts, there are various complex manufacturing steps that can make it difficult for customers in San Jose who are looking for speed and quality. Our software-powered manufacturing service combines all the needed manufacturing steps into a single easy process that includes design upload, checking DFM, material selection, quantity, and quotation. From just $50, customers in San Jose who order before 11 AM can get their parts manufactured and shipped the same day using a 24-hour delivery service.

Upload your designs online.

Select our materials online.

Get online quote in seconds.

Robots produce custom parts.

Track your orders online.

Start from just 1 part, delivered same day.Scale to 10,000 parts, at 93% off.

Our customers are leading their industries.

Industries in San Jose that lead their respective sectors choose our laser cutting & engraving services as we provide a precision service that can turn around parts in 24-hours using engineering-grade materials. Industries that prize such characteristics who have used Ponoko-made parts include electronics, biotech, chemical, medical, defence, and automotive. Not only is our service fully scalable from prototype to production run, but our ability to ship custom parts the same day reduces the time between design iterations from weeks to just days.

Bionic exoskeletons

Ekso Bionics

iOS POS hardware

Aila

Fulfillment systems

Berkshire Grey

Connectivity devices

Twilio

AI plant monitoring

Bowery Farming

iPhone testing stands

Apple

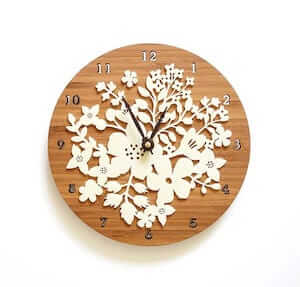

Wall clocks

Decoy Lab

Jewelry

Gio Gio Design

Lighting

Modern Maine

Internet satellites

Astranis

Aircraft

Joby Aviation

Autonomous vehicles

Velodyne Lidar

Scientific devices

Thermo Fisher

Cell therapy systems

Orca Bio

Delivery robots

Cyan Robotics

Laser cutting built for startups & enterprises.

Automatic IP protection.

Your online account terms bind us to protect your IP confidentiality, including a Non Disclosure Agreement.

Automated 30-day payment terms.

Upgrade to business terms today . Checkout online tomorrow. Pay in 30 days.

Free standard shipping.

For all USA shipments. Free material sample too.

Live chat with our technicians.

We’re online Monday - Friday, 9am - 5pm PT to assist you design highest quality & lowest cost custom parts.

99.3% precision part quality record.

Our ability to produce precision laser-cut parts with a dimensional accuracy of ±0.13mm is not just for singular parts, but for any size order in any material. We hold a precision part quality record of 99.3% for over 2 million parts manufactured across 33,000+ customers demonstrating our ability to not only provide precision but reliability and consistency too. There is a reason why so many high-tech industries in San Jose choose Ponoko for their laser cutting jobs; consistent results throughout a product's life cycle from the first part to the very last.

Standard quality procedure.

Our software, then design inspector, laser operator & quality manager quality check all orders.

Our promise.

If our software, robots, people or suppliers get it wrong, we’ll re-make & re-ship for free. No pesky returns.

We’re passionate about unleashing hardware creativity to advance humanity.

While we are proud of our ability to produce precision laser-cut parts, we are prouder to be involved with so many world-changing projects aimed at bettering humanity. Such projects include rapid COVID test kits, autonomous vehicles, cell therapy systems, and even internet satellites with some Ponoko parts currently orbiting Earth. Our ability to manufacture and ship parts the same day helps to accelerate the design process for engineers from weeks to just days, and this helps to unleash the full potential of every one of our customers.

Trusted by 35,000+ founders, CEOs, engineers, designers & scientists.

FAQ

Why choose Ponoko laser cutting services in San Jose?

What advantages does a laser cutter have over other cutting methods?

Can Ponoko offer laser-cut aluminum to San Jose customers?

Is laser cutting cost-effective?

What businesses in San Jose would benefit from laser cutting services?

Order laser cut custom parts from your laptop, delivered same day in San Jose.*

From $50 for just 1. 93% off for 10,000.