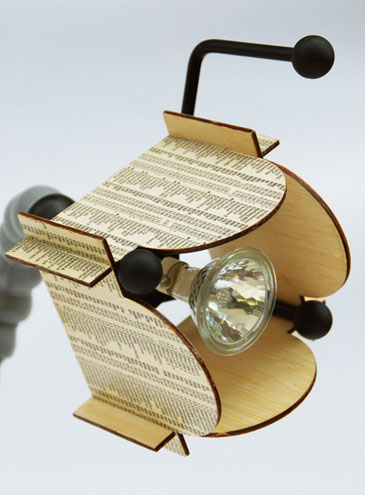

Warm fuzzy glow brought to you by laser cutting… and some electrical bit of course.

Portland resident Derek Taylor is the designer of Lamplabs – lighting that uses laser cut lampshades and other components. He joined Ponoko earlier this year after references from some online creatives who recommended it as a means to fabricate some offbeat ideas.

Portland resident Derek Taylor is the designer of Lamplabs – lighting that uses laser cut lampshades and other components. He joined Ponoko earlier this year after references from some online creatives who recommended it as a means to fabricate some offbeat ideas.

For Derek, the digital fabrication enables him to create components for his products that capture the essence of his early prototypes while minimizing their labor-intensive nature. In short, prior to Ponoko, his ideas couldn’t be made in a reasonable timeframe.

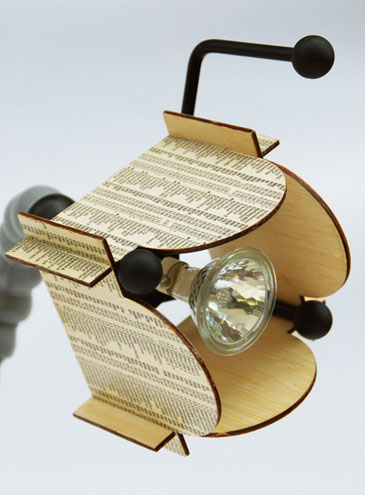

1.To install the lamp, you remove the faceplate from your outlet and screw this in. You then attach it at the top using a 3M command strip that will prevent damage to your paint if you remove the lamp.

1.To install the lamp, you remove the faceplate from your outlet and screw this in. You then attach it at the top using a 3M command strip that will prevent damage to your paint if you remove the lamp.

2.It‘s geared toward people that don’t want to hire an electrician or punch holes in their plaster walls, or for people that rent. It’s a quick method to add light to a hallway in an enjoyable way. I could also see a restaurant installing a half dozen of them along a wall for ambience.

How would you describe your creative process? There’s a famous anecdote about the founder of Lotus Cars, Colin Chapman. It is said that he would keep removing structural elements from a race car he was developing until the car broke under stress. When it did, he’d weld that last frame member back into the car. My creative process is much the same. I can appreciate minimalist design, but it just isn’t my aesthetic. Less is a bore to me. Therefore, I tend to work backwards from complexity towards simplicity and the ability to be mass produced. I stop when an object starts to look boring and then I add the last bit back in.

What material/s do you use/ have you used/are interested in using and why? I love using plywood or any other engineered wood product. There’s just so much potential. Give me enough plywood, drywall screws and a cordless drill and I can move the world.

Have you been surprised by anything in the Ponoko process? Everything I have made with Ponoko has come out great on the first try. Any mistakes I made in my designs have been caught by the server during the upload process. That really builds confidence.

Have you been surprised by anything in the Ponoko process? Everything I have made with Ponoko has come out great on the first try. Any mistakes I made in my designs have been caught by the server during the upload process. That really builds confidence.

Do you have any tips for other users? Design is iterative. You’ve got to keep fine tuning your designs to maximize shipping density, ease of assembly and material cost. When you get back the results from Ponoko, enjoy the culmination of the process, but set the idea aside for a bit and you’ll think of many ways to make it better. Secondly, cardboard mockups are your friend. You’ll see issues you can’t visualize in 2D and you’ll toss out ideas entirely when they have unanticipated results.

http://www.lamplabs.com kickstarter.com – Derek will be creating a project in order to fund a production run of about 25